The Invisible Inventory Shock: A surprising 43% of small businesses don't track their inventory, and 24% rely on simple accounting software. This lack of systematic inventory management leads to inefficiencies and potential revenue loss as businesses scale.

Inventory—Your Secret Success Weapon: Proper inventory management balances stock levels with customer demand, preventing costly overstock and stockouts. This optimization is vital for improving customer satisfaction and maintaining operational efficiency in e-commerce.

Multichannel Mastery Minimizes Mayhem: Integrating inventory systems across sales platforms ensures synchronized updates, preventing overselling, duplicate records, and enhancing consistent customer experiences, especially during high-demand periods.

Track and Report for Triumph: Accurate tracking and reporting provide real-time data on stock location and status, crucial for managing multichannel operations effectively and making informed forecasting and spending decisions.

Keep 'Em Coming Back: Ensuring efficient inventory practices leads to happy customers, boosting repeat business. Poor management may result in unhappy customers, risking lifetime business loss.

Inventory management is the most important and expensive part of an ecommerce business, yet 43% of small businesses don’t even track their inventory. Yeah, you heard that right.

Don’t. Track. Their. Inventory!!!

And, 24% of small business owners are just using simple accounting software for their inventory management.

Without an efficient process in place (not to mention, good dedicated software), managing inventory can become extremely difficult, especially as you scale.

And, it doesn’t have to be that way!

Inventory is the largest cost in an ecommerce business and, as your brand scales, management of that stock will inevitably become more complicated. It’s just math, folks.

Thus, this guide. I’m going to explain why inventory management is something that brands need to focus on and the various ways they can go about it.

What is Inventory Management For Ecommerce Brands?

Ecommerce inventory management is the strategic process of ordering, storing, tracking, and controlling inventory for online sales.

In many ways, it mirrors the process seen in brick-and-mortar retail stores, yet involves the extra dimension of monitoring each sale that occurs on your website, social selling platforms, and marketplaces.

Beyond what happens within your warehouses and how that’s presented in your online sales channels, inventory management also includes the parts before it lands with you—all the raw materials that ship from the manufacturers and suppliers.

So, finding a process and a tool that can integrate with your tech stack (ERP, accounting, ecommerce platform, sales channels, CRM, etc.) will enable you to easily maintain full stock visibility while scaling your business.

Why is Ecommerce Inventory Management Important?

How you manage your inventory determines whether you have the right amount of stock at the right time.

Done well, you can avoid both overstock and stockouts, which can lead to lost sales or excess costs.

Effective management balances inventory levels with customer demand, optimizes warehouse space, and streamlines order fulfillment, crucial for maintaining customer satisfaction and operational efficiency.

Having a solid ecommerce inventory management strategy also has a positive impact on the value of your brand. A business with good inventory management processes is worth a lot more to a potential investor or buyer should you choose to sell it.

As it touches on every aspect of your brand, poor inventory control processes can ultimately result in unhappy customers and a declining business outlook.

Let’s look at six benefits that show why inventory management is so important.

6 Benefits of Great Ecommerce Inventory Management Strategy

Every retailer needs an inventory management strategy, but that doesn’t mean it’ll be a good one. Done poorly, it can deeply affect your sales goals (or torpedo them altogether).

So, what do you get with better inventory strategies?

1. More inventory, better bottom line

A well-built inventory management system does more than tell you what’s in stock—it keeps that data in sync across every sales channel you operate on.

Whether you're selling on Amazon, Shopify, Walmart, or your own DTC store, multichannel integration means your inventory updates everywhere, instantly.

This prevents overselling, avoids duplicate stock records, and helps you deliver a consistent customer experience across the board. It also makes life easier during peak seasons or flash sales when inventory moves fast and mistakes get expensive.

Multichannel inventory integration also gives you a single source of truth.

You’ll see, in one place, how your stock is performing across marketplaces, where you need to restock, and where products may need a pricing or positioning tweak.

In short: more channels, less chaos.

Get real-time visibility across every platform with top-rated multichannel inventory software.

2. Less money and time wasted

Cash flow is important in any business, but an ecommerce store is a particularly cash-intensive business model.

Since you often pay for things months before you see any cash back in your bank account, you need to be strategic.

When your inventory management system is on point, you can stay on top of stock levels and make sure you have enough money to keep things moving smoothly. Overselling is a real risk!

Knowing your real-time inventory status allows you to restock right when you need to, so you don’t end up with too much cash locked up in inventory. Plus, you don’t want use up storage costs on dead stock.

3. Accurate reporting and tracking

Reporting and tracking capabilities enable brands to see where their stock is and for how long.

As your brand becomes multichannel or even omnichannel, expanding into multiple sales channels and scaling its audience, your reporting will be your savior.

With inventory strewn across warehouses, online marketplaces, online stores, physical locations, and delivery trucks, a singular tracking solution simplifies the complexities of your growing brand.

Inventory management reporting includes real-time information about each unit.

This is particularly important when you have stock in transit, as understanding the potential value of that stock will help you forecast your marketing spend.

4. Repeat customers

Unhappy customers often won’t come back, and you may have lost a customer for life.

If you know where your stock is, you can sometimes pre-sell the product to the customer before it is in the warehouse.

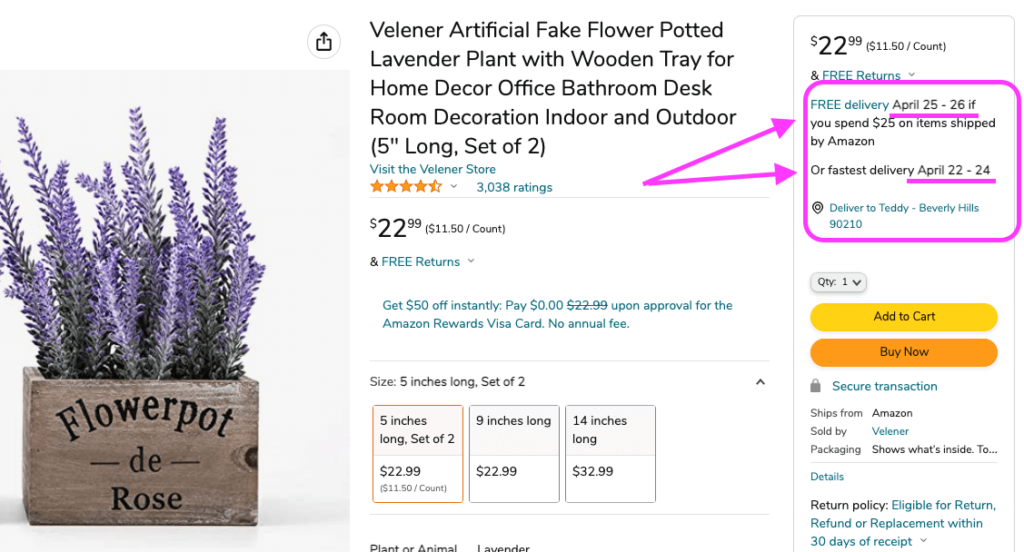

Amazon is good at this by showing longer shipping times when a product is not currently in stock but is on its way to a warehouse.

Maintaining customer satisfaction through effective inventory management is crucial, but it's equally important to recognize and address the challenges in inventory management that could impact customer loyalty and repeat business.

As you can see, having a solid inventory management strategy positively impacts your business value with your customers.

But beyond these fundamentals, understanding the specific benefits of inventory management software can further enhance your operational efficiency.

5. Less spending on warehousing

When your inventory management process has good reporting, you will know exactly how much stock you need to hold without overselling.

Your warehouse space is sacred and limited. You don't want to run into a situation where you've got too much stock and too little space.

Overstocking can be very expensive for an online business, in both inventory and storage costs. Maintaining the right levels will help you to reduce your total square footage of storage, lowering your costs.

6. Stock forecasting and seasonality

Different businesses will have peak seasons at different times throughout the year. The big selling periods are days such as Black Friday, Cyber Monday, and Christmas.

There are also different seasonal peaks for different products, for example, swimwear in the summer or chocolate around easter. Understanding these peaks is a huge part of inventory management.

A good inventory management process tracks the peaks to help you keep the right amount of stock in your warehouses.

The Ecommerce Inventory Management Process

Inventory management isn’t just about managing the stock you keep in the warehouse.

Managing the inventory starts right at the beginning when you place an order with your manufacturer, start making your products or you contact your suppliers to place a new order.

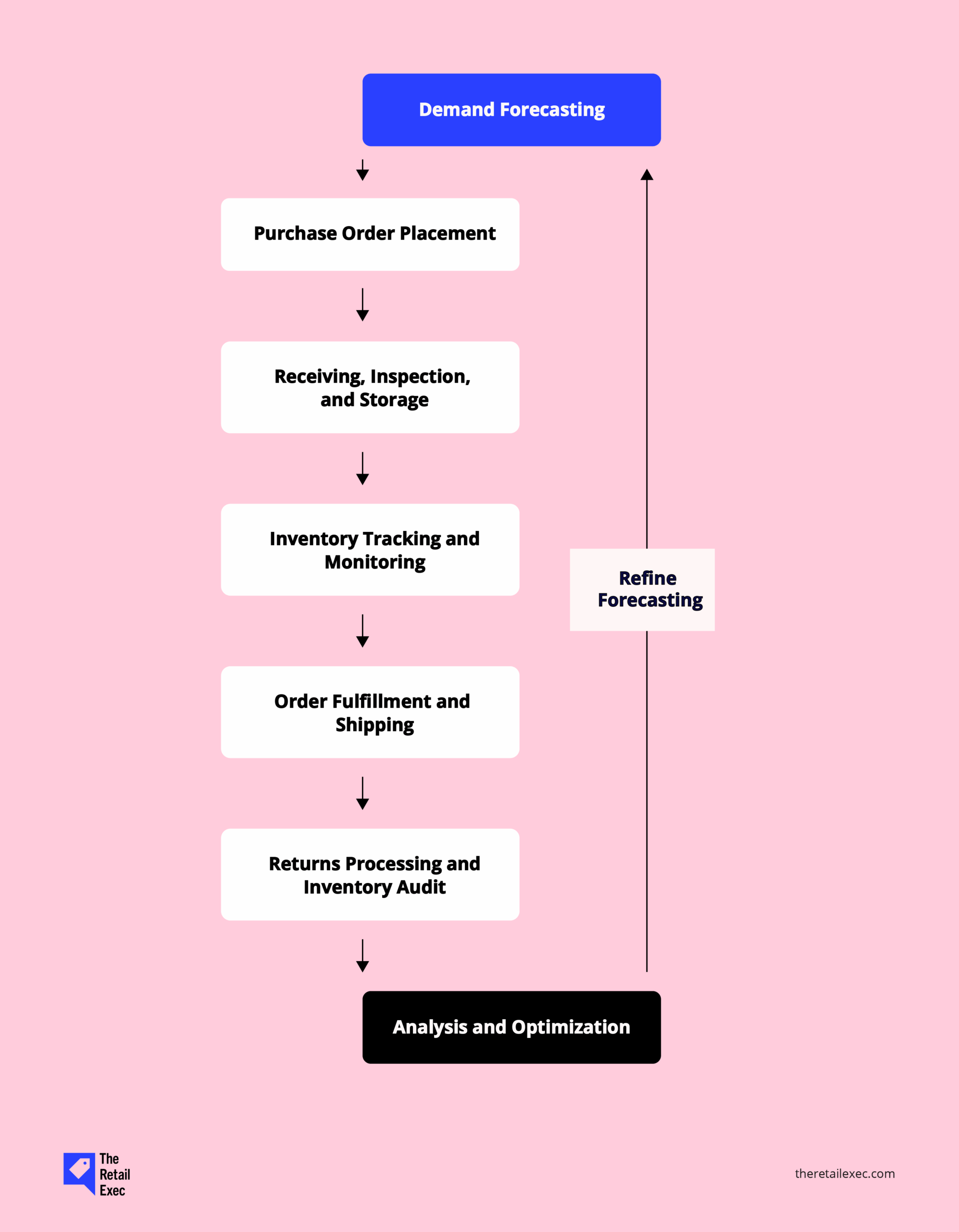

The key stages of inventory management are:

- Demand forecasting: Analyze historical sales data, market trends, and seasonality to predict future inventory needs.

- Placing purchase orders: Based on the inventory forecasting numbers, place orders with suppliers and manufacturers to replenish stock efficiently.

- Receiving, inspection, and storage: Upon arrival, inventory is checked for quality and quantity, then organized and warehoused for easy access, ready to be picked and packed. Tip: Simple layout changes, barcoding, and smart slotting can dramatically improve warehouse efficiency. More tips below.

- Inventory tracking and monitoring: Use inventory management software to continuously track inventory levels as items are sold, returned, or moved.

- Order fulfillment and shipping: Pick items from inventory to fulfill customer orders and prepare, pack, and ship orders, updating inventory levels accordingly.

- Processing returns and auditing inventory: Manage returns by inspecting, restocking, or discarding items, and conduct regular cycle counts to identify discrepancies.

- Analyzing and optimizing inventory data: Use data from the inventory management process to identify areas for improvement, such as adjusting reorder points or optimizing storage solutions, and refine demand forecasting to complete the cycle.

There are a lot of things to manage, which is why I use cloud based inventory management software to help me sort it from wherever I am.

As promised: Warehouse management optimization tips

Your warehouse isn’t just storage—it’s a key part of how fast and accurately you fulfill orders. A few small upgrades can boost efficiency without major investment.

- Add barcode scanning to speed up receiving, picking, and inventory updates.

- Slot fast-moving SKUs closer to packing stations to reduce pick times.

- Define clear zones for storage, packing, and returns to avoid bottlenecks.

- Cycle count high-value items regularly to stay accurate without full audits.

For scaling brands, a warehouse management system (WMS) integrated with your inventory tools can take this to the next level.

Ecommerce Inventory Management Techniques For Max Efficiency

Whilst there are many different techniques for managing your inventory, some aren’t really relevant for a small ecommerce business owner.

Here are all the inventory techniques you should know about as you set about building a smart strategy.

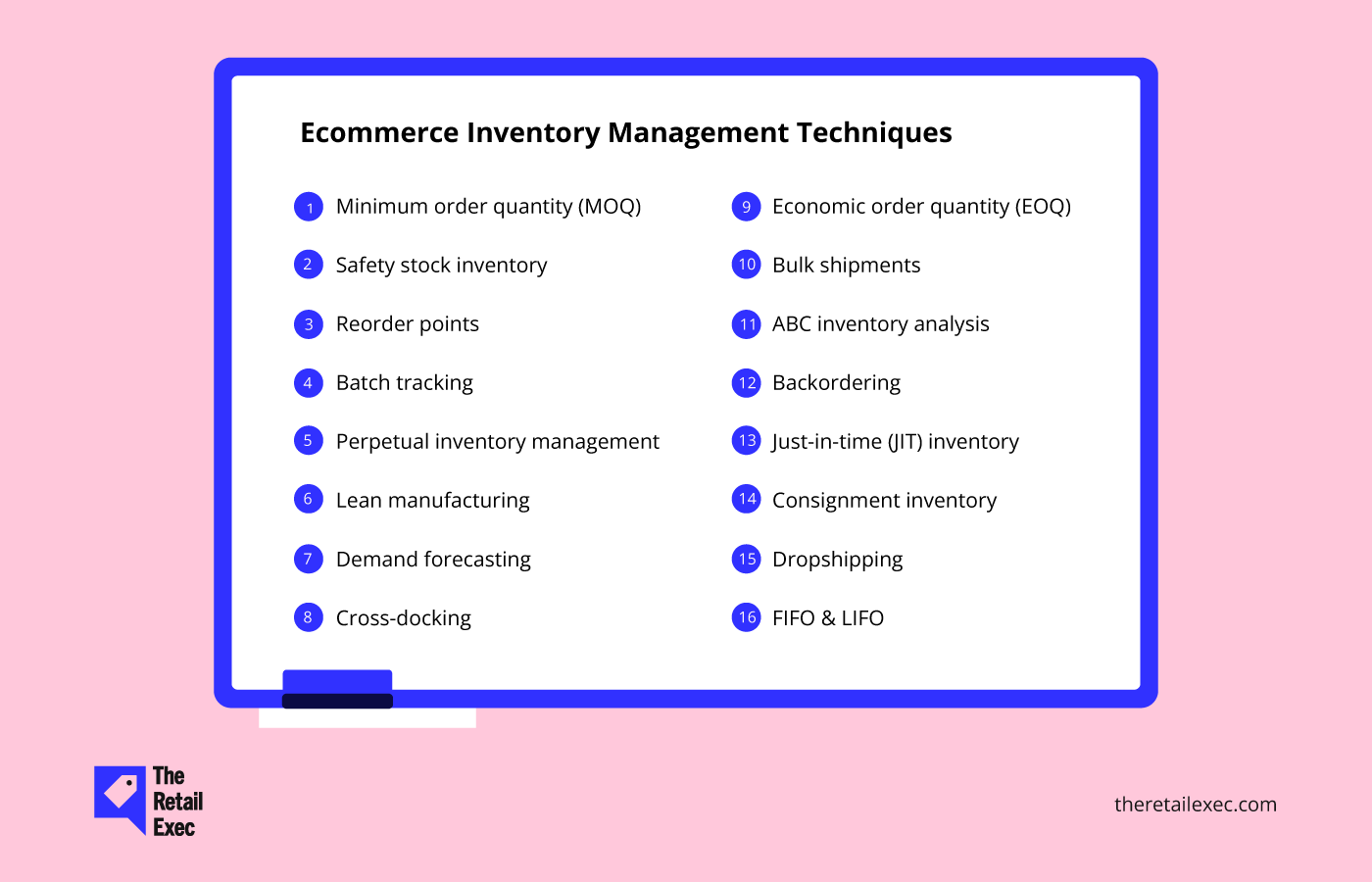

Minimum order quantity (MOQ)

Minimum order quantity (MOQ) is a number set by your supplier, dictating the smallest amount of stock you can order at one time.

The supplier can then reduce shipping costs for orders and maintain repeatable fulfillment processes for quicker shipments. That’s great and all for the supplier, but it can make it more difficult for sellers to keep a lean inventory.

Safety stock inventory

Safety stock, like the name suggests, is an amount of inventory you keep in stock in case of demand spikes or supply chain disruptions.

It’s valuable for avoiding that “out of stock” notice on your product pages.

Brands use historical sales data, delivery lead time, inventory holding costs, and the costs of stockouts to determine the ideal level of safety stock to keep.

Reorder points

Related to safety stock, reorder points are the level of inventory you hit that automaticall triggers a new purchase order. These points are set on an individual SKU basis using demand, delivery times, and safety stock on hand.

Batch tracking

Often used for perishable items, brands can group products together based on unique identifiers with batch tracking. These identifiers are usually batch or lot numbers.

By tracking this way, brands can easily QA products and suss out defective or expired product by its origin and production date.

Perpetual inventory management

A pretty standard practice today, perpetual inventory management means that you track everything in real time. So, when you create a purchase order with a supplier, as stock comes in to your warehouse, as your products sell and ship out.

Modern inventory management software and scanning tech makes this a breeze.

With automation, updates happen instantly as sales occur, orders are fulfilled, or returns come in—no manual data entry required. You get real-time accuracy with none of the spreadsheet chaos.

Lean manufacturing

The lean manufacturing process, made famous by Toyota, can apply to more than just the fabrication of products.

This methodology, along with Six Sigma and the conglomerated Lean Six Sigma, aims to identify inefficiencies in your system and eliminate them to streamline your operations.

Each company’s processes differ, so implementation can be unique to your underlying issues.

Demand forecasting

It doesn’t take a crystal ball to have a good idea of your future product demands. It just takes enough sales data to make informed guesses. Like weathermen.

The point of this prediction is to buy like Goldilocks, not too much and not too little—just right. If done well, you avoid stockouts and overstocking. YAY!

Cross-docking

Related to just-in-time delivery methods, cross-docking is the method of receiving products just before shipping them out. It effectively cuts out the storage step of the process.

Orders come in, get checked into inventory, and are loaded up to ship out.

As with any just-in-time method, coordination has to be nearly perfect to avoid slowdowns.

Economic order quantity (EOQ)

Economic order quantity is a principle wherein you ensure there’s enough stock to keep up with demand but not so little that you are always out of stock.

Too much inventory can incur higher storage fees, wasted products, and shipping fees because of the volume. On the other hand, too little stock can mean disappointing your customers and losing out on potential sales.

Working out your EOQ will be different for all businesses, and it’s something you can improve over time. This is because you don’t know your sales velocity until you start selling.

In my inventory management system, I work out the sales velocity over the last 3-12 months to ensure new orders always have enough quantity for around six months of sales.

This usually gives me enough runway to place a new order with my manufacturer and get the stock back on the shelves before current stock runs out.

Bulk shipments

Generally, the larger your order is, the cheaper your cost per unit and profit will be.

When you place larger orders with manufacturers or wholesalers, you get the best prices, and often, preferential treatment in busy times.

Plus, you save money on shipping and freight by using whole containers, which are more cost-effective than less than container load (LCL) shipments.

Most ecommerce brands will move to whole containers at some point, especially if they are growing and seeing high customer demand.

For example, if you’re selling on Amazon, Etsy, or eBay, you can get high sales volumes quite quickly with the right products.

The main downside to large bulk shipments is paying a large upfront cost to the manufacturer. You may also have higher warehousing costs as a result.

There is also a risk that your products don’t sell, increasing warehousing costs even further.

If you deal in large volumes of products regularly, enterprise-grade inventory management software is the way to go.

ABC inventory analysis

Some of your products are more important than others. With ABC inventory analysis, you can make sure your focus is on the products that will make you the most money.

You split up your SKUs from most important (A) to least important (C), with middling items taking up the space between (B). All based on a metric like annual inventory value.

A-items are those with a higher investment return, often taking up 20% of your storage but responsible for 80% of your revenue. When you decide where to spend your money, this list of products will get priority.

The main downside to ABC management is it takes time to set it up, as you first need to understand your products’ sales velocity.

ABC analysis is commonly used to help with cycle counts, wherein you do inventory counts on A-items more frequently than B- or C-items to prioritize the money stock.

Backordering

Backordering is when you continue to sell a product even when it’s out of stock.

This process only works if you can restock quite quickly after going out of stock, as most customers are not likely to wait for a long time for replenishment.

The exception is if your brand has a strong following of fans willing to wait longer for your products (e.g., fans of Apple products).

The key to a successful backordering process is communicating with customers about when they can expect their products to arrive.

As we discussed earlier, Amazon excels at highlighting the delivery time and showing a customer when they can expect to receive a product that is out of stock.

Replenishment is a strategy, not a scramble. Use inventory replenishment tools to plan ahead—and container tracking software to avoid surprise stockouts.

Just-in-time (JIT) inventory

This is a more risky inventory management technique, as you only order inventory a short time before the sale.

This is the technique that most supermarkets use due to sell-by dates on fresh foods.

The pandemic highlighted this technique’s weakness, as trucks couldn’t successfully cross borders in time to deliver all the food.

However, there are some benefits.

Just-in-time inventory management lowers the amount of stock you keep in warehouses, reducing costs and removing many wasted products. It is also great for cash flow, as you don’t need to spend large amounts upfront.

JIT only works when you have a mature business and understand seasonal changes, sales trends, and your own historical sales data.

On top of this, you need very reliable suppliers who can deliver your stock with tight lead times to keep your customers happy.

Consignment inventory

Consignment is where the manufacturer or wholesaler sells their stock on your ecommerce website, but you don’t pay the manufacturer/wholesaler until a customer has purchased it.

This is a great system for ecommerce sellers as there is very little risk involved. You don’t have any money tied up and you can quickly increase your product range, keeping operations agile.

It also means you won’t have additional warehousing costs and wasted stock, as the purchase order is made when the customer pays for their product.

Typically, this type of relationship works when the manufacturer is confident that the ecommerce brand can sell the stock. As an ecommerce seller, this could be a great option to test new products without risk, but you must be aware that the profit margin will typically be much lower.

So if you sell a product on consignment and it is successful, it might be worth considering a bulk order in the future.

For more on consignment: What is consignment and how to approach it?

Dropshipping

A dropshipping store never holds stock and sells products directly from another brand or manufacturer.

This is similar to how marketplaces work.

Most ecommerce platforms can be used for dropshipping by connecting a simple integration or plugin. You’ll find tons of apps on the Shopify App Store for this exact thing.

Usually, the other brand will pay a fee for their products appearing or being sold on your site, so it’s a good way to increase your product range without too much risk.

Dropshipping solutions have had quite a bad reputation for selling cheap products sourced directly from Aliexpress. However, new dropshipping sites in specific niches are gaining traction, such as Peace In The Wild and Not On The High Street.

FIFO & LIFO

Two main methods are used to understand the value of the inventory you have in stock or cost of goods sold (COGS): FIFO and LIFO.

FIFO means “first in, first out,” and LIFO means “last in, first out.”

These terms are important when valuing your stock for bookkeeping and accounting, as they will help you understand how much your warehouse stock is worth.

FIFO and LIFO are also used to manage the stock in a warehouse.

If the stock is perishable, like food, the oldest stock would be sold first as it might be close to the sell-by date. FIFO is the perfect method for this.

But there is no sell-by date for products such as electronics or tools, so it doesn’t matter if the new stock is sold first. Thus, you may use a LIFO method for this type of product.

Inventory Management Formulas For Key Metrics

Really powerful tools are great, but if you don’t know what KPIs to track, you’ll be like a toddler in a race car. So, let’s quickly look at each metric and the formula you’ll need to find it.

Inventory turnover

Formula: Inventory Turnover = Cost of Goods Sold / Average Inventory

Inventory Turnover is a crucial metric indicating how often your inventory is sold and replenished within a specific period.

High turnover rates signify efficient inventory usage and robust sales performance.

Reorder point

Formula: ROP = Average Daily Demand * Lead Time

Calculating the reorder point (ROP) ensures you replenish inventory precisely when needed, maintaining a balance that meets customer demand without leading to excess stock.

Carrying cost

Formula: Carrying Cost % = (Inventory Holding Costs / Total Inventory Value) * 100

Understanding your carrying cost of inventory helps in identifying the expenses associated with storing unsold inventory, encouraging strategies to minimize these costs without sacrificing sales.

Economic order quantity (EOQ)

Formula: EOQ = sqrt((2 * Demand Rate * Order Cost) / Holding Costs)

The EOQ formula finds the ideal order quantity that minimizes the combined costs of ordering and holding inventory, optimizing stock levels and reducing unnecessary expenses.

Safety stock

Formula: Safety Stock = (Max Daily Sales * Max Lead Time) - (Average Daily Sales * Average Lead Time)

Maintaining safety stock is your safety net against unpredictable demand and supply chain delays, ensuring you can always meet customer orders promptly.

Gross margin return on investment (GMROI)

Formula: GMROI = Gross Margin / Average Inventory Cost

GMROI assesses the profitability of your inventory investment, comparing the gross margin earned to the inventory cost. It's a measure of how effectively your inventory contributes to your business's financial health.

Stockout rate

Formula: Stockout Rate = (Number of Stockouts / Total Demand) * 100

This rate provides a percentage that indicates how often stockouts occur compared to the total number of items customers wanted to purchase.

A high stockout rate can signal issues with inventory management, demand forecasting, or supply chain efficiency. Unlike stockout costs, the stockout rate focuses solely on the occurrence of stockouts, not on their financial impact.

Inventory shrinkage rate

Formula: Inventory Shrinkage Rate = [(Recorded Inventory - Actual Inventory) / Recorded Inventory] * 100

Inventory shrinkage can significantly impact your business's bottom line, affecting everything from inventory accuracy to profit margins.

Understanding and minimizing shrinkage is essential for maintaining operational efficiency and customer satisfaction.

Common Ecommerce Inventory Management Challenges (And How to Solve Them)

Even with the right tools and workflows, inventory management is rarely smooth sailing. Ecommerce brands run into predictable—but critical—challenges that can derail growth, eat into margins, or frustrate your customers (and team).

Here are some of the biggest issues—and how to get ahead of them.

1. Overselling and stockouts

Selling what you don’t have is a fast track to refunds, bad reviews, and a customer who probably won’t return.

Why it happens:

- No real-time stock syncing across sales channels

- Manual entry errors

- Delayed updates from 3PLs or warehouses

How to fix it: Use inventory software that syncs stock levels automatically across every marketplace and store you sell on. Set safety stock thresholds and auto-reorder triggers to prevent sellouts.

2. Inaccurate or outdated inventory data

When your inventory data is off, every decision based on that data—purchasing, forecasting, budgeting—gets riskier.

Why it happens:

- Disconnected systems

- Manual updates

- Lack of standardized processes across locations

How to fix it: Implement cloud-based inventory tools that pull data from across your sales, warehouse, and fulfillment operations. Layer in cycle counts and automated audits to catch discrepancies early.

3. Overstocking and tied-up capital

Too much stock sitting in a warehouse? That’s cash you can’t use elsewhere—plus it racks up storage costs.

Why it happens:

- Poor forecasting

- Minimum order quantity pressure from suppliers

- No visibility into slow-moving SKUs

How to fix it: Use demand forecasting tools to project needs based on past sales and seasonality. Adopt techniques like ABC analysis to focus inventory investment on your best performers.

4. Lack of visibility across your supply chain

If you’re not sure what’s inbound, what’s sellable, and what’s tied up in returns or transit—you’re flying blind.

Why it happens:

- Fragmented systems

- Lack of warehouse integrations

- No real-time reporting

How to fix it: Look for inventory platforms with end-to-end visibility, from supplier to shelf to shipment. Integrate with your WMS and order management system for a clear, live view of stock movement.

5. No process for handling disruptions

Supplier delays. Sudden demand spikes. Inventory stuck at a port. Without a plan, these throw your whole operation off balance.

Why it happens:

- No backup suppliers

- Inflexible stock strategies

- Over-reliance on just-in-time methods

How to fix it: Build in contingency plans, carry some safety stock, and diversify fulfillment so you’re not relying on a single provider or warehouse.

What Inventory Management Tools Should You Use?

Many of the inventory techniques we’ve covered so far can become labor-intensive fast.

That’s why most ecommerce brands eventually turn to inventory management software that automates key workflows—and helps keep operations efficient, accurate, and scalable.

As mentioned, when I started selling online, I used a simple spreadsheet to help me manage my inventory, but this quickly became too time-consuming. I needed to choose inventory management software.

Automation reduces manual errors, improves stock visibility, and saves time. The right platform will:

- Sync stock levels across your channels in real time, which helps eliminate overselling.

- Auto-generate purchase orders when you hit reorder points.

- Track inventory as it moves—from warehouse receiving to fulfillment—without manual updates.

- Flag anomalies before they become costly problems, like low safety stock or unexpected demand spikes.

If you're selling across multiple SKUs, warehouses, or channels, automation isn’t a luxury—it’s table stakes.

Your inventory system should also plug into the rest of your tech stack: your ecommerce platform, fulfillment providers, warehouse tools, accounting software, and wherever else your inventory data needs to live.

We’ve gone into lots of detail about the best inventory management software and the benefits of each one.

Here are our top 10 picks for inventory management tools:

Choosing software is just step one. The bigger win is getting automation working for you in the background—so you can focus on growing the business, not just managing spreadsheets.

Scale Your Brand With Smarter Inventory Practices

Inventory management is one of the most important parts of an ecommerce business. It can get complicated, so it is good to implement best practices as early as possible in your business.

Understanding where your stock is at any one time will help your business to make more sales and keep customers happy, so proper ecommerce management is very important to get it right.

However, understanding this can be a full-time job is why inventory management software can help you keep on top of it all.

Keep up with other ecommerce software reviews, news, and tips by subscribing to the Ecomm Manager newsletter.

Ecommerce Inventory Management FAQs

We talked about A LOT of stuff here, but let’s end with a few Qs and their requisite As on a few final inventory management topics.

How can ecommerce brands minimize human error in inventory management?

Moving away from manual inventory management systems and adopting automated solutions helps eliminate human error, so you can have more precise and reliable inventory tracking and management.

What strategies can be employed to reduce inventory shrinkage in ecommerce?

To reduce inventory shrinkage—loss due to theft, damage, or error—ecommerce brands can implement regular audits, enhance security measures, and use inventory management software for accurate tracking of stock levels.

How can ecommerce businesses leverage technology to enhance inventory management?

Advanced inventory management software helps ecommerce retailers automate inventory counts, monitor safety stock levels, set automatic reorder points, and maintain accuracy across multi-SKU and multi-warehouse inventories. This reduces human error and improves operational efficiency, enabling businesses to meet customer demand effectively.

What are the main ecommerce fulfillment methods, and how do they impact inventory?

There are a few core fulfillment models you’ll run into:

-

Fulfillment by Amazon (FBA): Amazon handles your storage, shipping, and customer service. You get speed and scale, but you’ll need to track inbound inventory carefully to avoid stockouts or storage fees.

-

Fulfilled by Merchant (FBM): You handle storage and shipping, either in-house or via a 3PL. This gives you more control—but it also means tighter coordination between your inventory system and your warehouse or logistics provider.

-

Dropshipping: You don’t carry inventory at all. Products ship directly from a supplier. Easy to start, but limited visibility and control over stock levels.

Each model affects how you track and manage inventory. Choose based on your business model, scale, and how much control you want over fulfillment.

How can ecommerce brands make their inventory management more sustainable?

Sustainable inventory management is about reducing waste, improving efficiency, and aligning with eco-conscious customer values. A few ways to do this:

-

Optimize stock levels to avoid overproduction and excess storage (less dead stock = less waste).

-

Use eco-friendly packaging materials that are recyclable or biodegradable.

-

Streamline your supply chain with fewer, smarter shipments to cut down on transport emissions.

-

Forecast demand accurately to prevent unnecessary reorders or markdowns.

Sustainability isn’t just good for the planet—it can also reduce costs and build brand trust.