Bean Counting for Grown-Ups: It's easy to lose track of inventory like canned beans, leading to overstock and expired goods.

Retail's Rotten Reality: Overstock and expired products can significantly impact profits, making accurate inventory management crucial for businesses.

The Marvel of Matching Records: Ensure your physical inventory matches your records to avoid costly discrepancies on your shelves.

Reconciliation Saves the Day: Inventory reconciliation helps businesses accurately track stock, preventing both overstock and waste.

Pro Tips for Better Inventory: Implement expert-backed strategies for effective inventory management to keep your shelves in top shape.

You keep buying cans of beans every time you go to the supermarket, because you're not exactly sure how many you already have.

And today, you finally check the pantry. Lo and behold: there are 9 cans… and 4 of them are already expired.

Oof.

Thankfully, beans are cheap. But in retail? The cost of overstocking, lost inventory, or expired products can seriously eat into your profits.

It’s important for what you think you have and what’s in your system to match what’s on your shelves.

This is where inventory reconciliation comes in.

In this piece, I’ll walk you through an efficient reconciliation workflow and share expert-backed tips to help you successfully manage your inventory.

What is Inventory Reconciliation?

Inventory reconciliation is the process of checking whether your physical inventory counts match what you have on record.

It’s your frontline defense against stock discrepancies and their operational impacts, issues like overstocking, lost sales, and unforeseen costs.

Proper inventory reconciliation helps you fix the numbers. But more than that, it helps you understand why they’re off in the first place, so it doesn’t happen again.

But why do inventory discrepancies happen, anyway?

That's a trillion-dollar question. Specifically, $1.77 trillion—that’s the cost of inventory distortion the retail industry faced in 2023.

Inventory distortion, also known as stock shortages or stockouts and overstocking, happens when you don't have a clear picture of your real numbers.

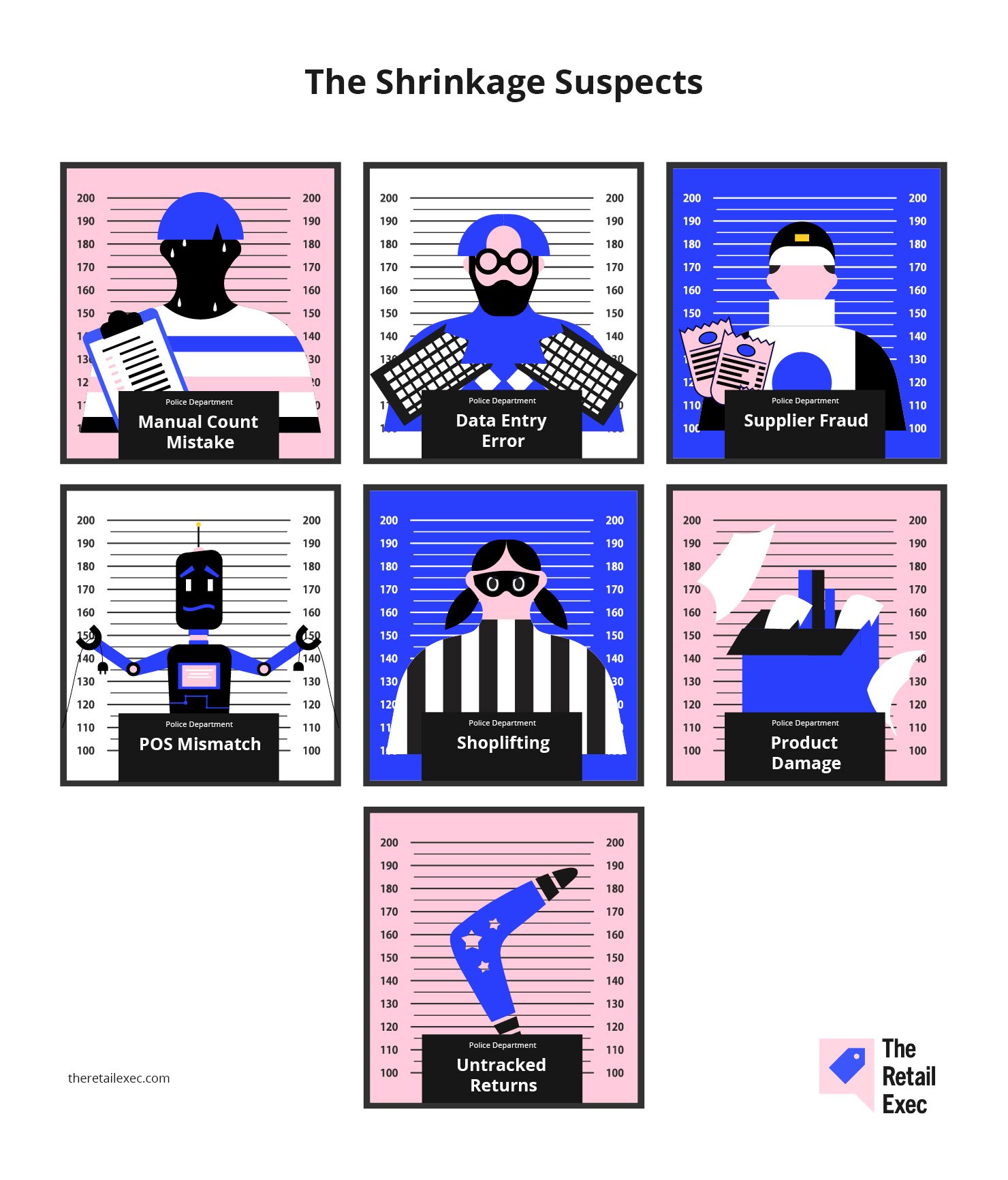

So, how does shrinkage (and its sneakier cousins) find their way into your business?

- Simple miscounts. Manual counts gone wrong. It happens, especially if you don’t have the right equipment.

- Data entry errors. All it takes is one wrong digit to skew an inventory report.

- POS mismatches. Point-of-sale (POS) systems and inventory systems don't speak the same language.

- Supplier fraud. Invoices that don't match what was delivered.

- Shoplifting/theft. Sadly, both customers and employees can commit these misdemeanors.

- Product damage. Broken, expired, or unsellable items left unaccounted for.

- Untracked returns. Refunds or exchanges that never make it back into the system.

Regular inventory reconciliation helps you get ahead, keeping your records up-to-date, so your business doesn't suffer from the collective blow.

How to Reconcile Inventory: 6 Easy Steps to Better Stock Control

Give your stockroom a reality check.

I’ll walk you through an efficient inventory reconciliation process that you can easily replicate. To make this even more digestible, let’s look at how Finn’s Things, a fictional brand that makes playful, durable pet accessories, will perform each step:

1. Choose a method

Pick a reconciliation method that matches your business needs. Then stick to it—consistency is key to spotting trends over time.

Here are the most common methods and where they make the most sense:

| Method | Definition | Works for |

|---|---|---|

| Seasonal method | Reconciles inventory around seasonal peaks—like end-of-quarter, holidays, or big sales cycles. | Retail brands with major seasonal swings |

| ABC method | Categorizes inventory by value or velocity: A (top-sellers), B (mid-tier), and C (slow movers) | High-SKU retailers, manufacturers, wholesalers focused on prioritizing effort |

| Arbitrary method | Random spot checks, without a set order or priority. | Small businesses or lean teams that need flexible, on-the-fly checks |

Since Finn’s Thing has a high SKU number, they opted for the ABC method. Their dog collars (available in funky prints and neon colors) are their best-selling items, so they prioritize this category when reconciling inventory.

2. Count physical inventory

Once you’ve chosen the method, it’s time to put your inventory count under the microscope.

Depending on your goal, you can choose between:

- Full inventory: Review all inventory, ideal for major audits.

- Cycle count: Count smaller sections of your inventory (like one product category, SKU type, location) on a rotating basis. This is easier to fit into a busy schedule.

Finn’s Things opts for cycle counts to keep track of high-volume items. They count their “A” items every month, “B” items quarterly, and “C” items twice a year.

3. Compare to digital/POS records

Ready for the moment of truth? It’s time to check whether your actual inventory numbers, the resulting figure after your physical count, match your digital records.

Compare the total number of items in your store with the inventory levels recorded in your POS system. This step shows you if you have missing, extra, or miscounted items.

Finn’s Things pulls data from their POS system, and compares it with what’s actually in their stockroom. Their experience has taught them that even a slight mismatch of 3 to 5 units can cause overselling or unnecessary reorders.

4. Investigate discrepancies

If the numbers don’t add up, you need to figure out why. See what's missing, and look into potential shrinkage causes.

For example, the team behind Finn’s Things notices they’re missing five units of the best-selling dog collar in neon orange.

Here’s what they did:

- Check the recent purchase orders and the received inventory

- Review financial reporting and sales records for returns

- Check with the marketing team if any products were used for events/samples/etc.

After some digging, they realize a supplier has marked them as delivered, yet the shipment never made it to the warehouse.

As a result, they know that the discrepancy isn’t internal, but rather a receiving issue.

But let’s say, they check their records, which turn out to be squeaky clean. They can chalk the cause of shrinkage down to theft or fraud.

Either way, tracking down the source helps you take corrective and preventive action.

5. Update records and generate reconciliation report

Where and how things went off track is crucial. But so is updating your data to make sure it’s clean and useful going forward.

Here’s what the Finn’s Things team includes in their inventory reconciliation report:

- Document the discrepancy and its resolution

- Note who performed the reconciliation and when

- Include comments or notes for special cases

- Store reconciliation reports from each count in a shared folder

Optional: You can add a column on inventory valuation to record the financial impact of discrepancies on your business.

I’ve created this downloadable Excel reconciliation template for you so you know which to keep tabs on:

Downloadable Excel Reconciliation Template

6. Set regular reconciliation intervals

Last, but not least, plan the next one. Inventory reconciliation requires repetition, and the timing will depend on your selected method, products, and goals.

The more consistent your team is, the more trustworthy your data becomes.

Sounds simple, but it's tedious and time-consuming, so you’ll need some tricks up your sleeve to make it more efficient.

Inventory Reconciliation Strategies That Improve Profitability

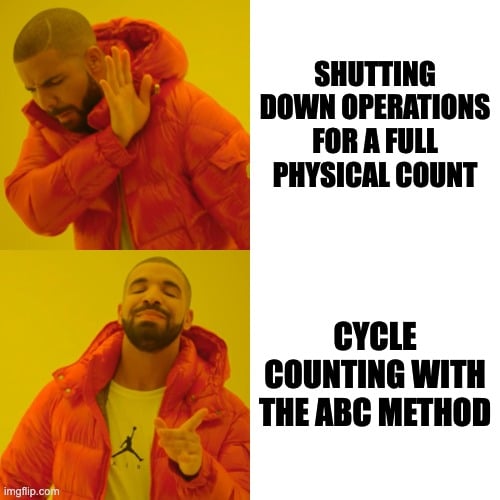

Businesses often shut down operations for a few days or work past their usual schedules to carve out time for inventory reconciliation.

But if you work smart, you can perform inventory reconciliation to boost inventory accuracy without significant disruptions.

Here are some expert-approved tips:

Standardize with a clear SOP

A standardized inventory reconciliation process supports consistency and repeatability. So step one is to build a standard operating procedure (SOP) your team can follow like clockwork.

It’ll look a little different from other businesses’, depending on its products and workflows. But at its core, every SOP should clearly do the following:

- Assign a lead: Who runs the show ? Identify key personnel responsible for counts, data entry, oversight, and follow-ups.

- Set the schedule: When and how often should you conduct inventory reconciliation? You can schedule downtime during off-seasons or avoid it by arranging the checks after operations.

- Prep the tools: What to add to their arsenal? Pick out and prepare the systems and equipment your staff will need to get the job done.

- Outline documentation steps: What happens after the count? Give clear instructions on how to record issues, and educate your staff on how to record and resolve discrepancies.

All these work together to create an SOP that reduces inventory error margins and ensures your team knows what to do when they do creep in.

Make sure to audit and update your reconciliation process at least once a year.

Use the ABC method to prioritize high-impact inventory

Why the ABC method, you ask?

Because while you love all your products, each deserves a different level of attention.

Here’s a quick refresher: The ABC method follows the Pareto Principle, which helps you zero in on the 20% of products that bring in 80% of your revenue.

By identifying which products are worth the extra effort—the juice that’s worth the squeeze, if you will—you can spend more time reconciling the inventory that contributes to your business' success.

Here’s an example of how ABC cycle counting might look:

| Category | Which products? | Revenue % | Inventory % | Cycle count frequency |

|---|---|---|---|---|

| A | High revenue/demand goods | 80% | 20% | Bi-weekly to monthly |

| B | Average to high revenue/demand goods | 15% | 10% | Quarterly |

| C | Low revenue/Low demand goods | 5% | 70% | Semi-annually |

Of course, how you define “high value” will depend on your business.

For some brands, it might be strictly about revenue. But you might want to add in factors such as customer demand, profitability, turnover rate, or even, business strategy.

Whatever your criteria, your Category A products need to have the tightest inventory control and monitoring. They simply deserve the cleanest records for bringing in the big bucks.

Implement cycle counting instead of full physical counts

Inventory cycle counting breaks the job into bite-sized pieces. You only work on a sample of inventory at a time.

It’s great for retailers with lots of SKUs, and generally, for avoiding the dreaded full-stop inventory count that can stifle or shut your business operations for days on end.

There are three types of cycle counting, depending on your goals:

- ABC cycle counting: Sound familiar? Yeah, we just talked about it above—prioritize your cash cows (Category A) and count them more frequently than Categories B and C.

- Random sample cycle counting: Do you sell similar products across multiple categories? This might be your match. Choose which product groups to count, then exclude them from future cycles until all product types have been accounted for. Also known as diminished population counting.

Control group cycle counting: Want to test the effectiveness of your inventory reconciliation process? This one’s for you. You repeatedly count a small, consistent group of items over a short period. Once you’ve ironed out errors and fine-tuned the process, you can roll it out across the rest of your inventory.

So wait a second: Does this mean full physical counts have outlived their usefulness?

Not at all.According to Karl Threadgold, managing director at Threadgold Consulting:

Full physical counts still have a place, usually annually, at year-end, or after a system change or warehouse reorganization.

But cycle counts make sure your data is fresh on a regular cadence, helping you catch discrepancies before they become costly headaches.

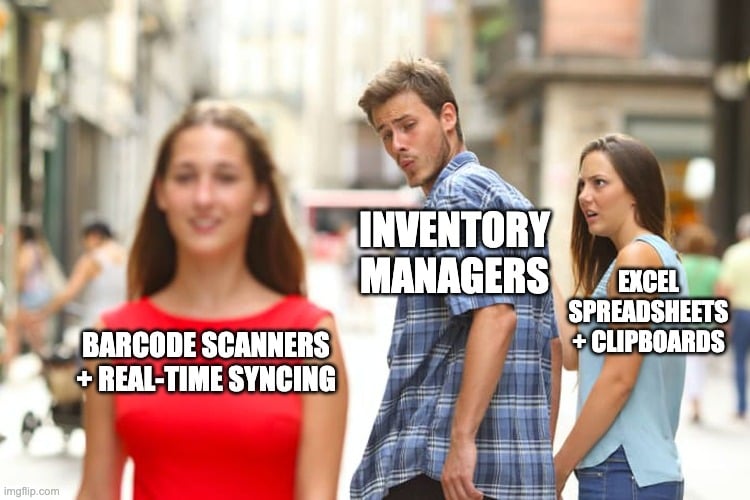

Leverage inventory management software for smarter counts

Inventory reconciliation is a tedious process, so it’s frustrating when, after all that effort, your numbers still don’t match.

The remedy? Invest in or update your inventory management software (IMS).

A good platform automates reconciliation, so manual errors, like miscounts and data entry errors, that plague your process go out the window.

Here’s proof:

Australian music store Big Music used to spend entire weekends once a year on full store-wide stocktaking and inventory reconciliation.

Founder Richard Berkman said everyone on the team hated this busy time.

After switching to Cin7, however, they’re able to shift to rolling inventory reconciliation. According to Richard, this is possible because with the tool, you can break the inventory down into components, and work on a section, a brand, or a range of things at a time.

No fuss, no shutdowns.

Source: Cin7

Other inventory management features you’d want to have include real-time discrepancy alerts, POS integration, mobile data capture, barcode scanning, and cycle counting support.

According to Georgia Leybourne, Linnworks’ Chief Marketing Officer:

IMS should be the foundational backbone of your inventory count.

Real-time centralized inventory management software auto-syncs inventory counts on each and every point of sale before it becomes a problem.

Without that system support, investigating inventory discrepancies is a constant manual initiative involving multiple system logins and human counts on each system.

The moment you’ve finished and think you’ve got a clear picture, you’ll likely be out of date again with more discrepancies coming your way.

However, the more value-added peripherals you engage, the more accurate this system will prove to be.

Barcodes, QR codes, RFID, security systems, and all kinds of tracking tools will reduce the potential of discrepancies within your IMS if fully connected and operational.

Tools like Linnworks and Cin7 have advanced features and integrations that can give your staff the support they need in this otherwise grueling process.

Listed below are some other recommendations:

Integrate your POS system for real-time reconciliation

Just because you’re already operating in a tech-enabled environment doesn’t mean you no longer have a blind spot.

As I mentioned previously, one of the biggest culprits of inventory discrepancies is a disconnect between your point-of-sale (POS) system and inventory software.

These two critical systems need to communicate with each other.

If your POS isn’t updating inventory levels in real time, you risk overselling products or reordering what you already have. Both aren’t good for business.

Choose a platform that integrates smoothly with the rest of your ecommerce tech stack. A system keeps all your data on the same page, so you're not constantly playing catch-up.

Tools like Square even offer basic inventory tracking features to help monitor stock levels.

Of course, nothing in business is really ever “set it and forget it”.

Jeremy Fitzgerald, CEO of 86 Dead Stock (an online marketplace for the hospitality industry) advises, “Syncing POS with inventory systems requires careful setup and regular maintenance. I recommend periodic audits of menu item setups to ensure they reflect actual products used.”

Check which of our highly-recommended tools will work for your business:

Use barcode scanners to speed up and validate counts

Barcode scanning is a trusted technology for reducing manual entry errors and speeding up the counting process.

Simply point and wait for the beep, et voilà—the info is in the system. But to get to this level of easy-mode efficiency, you need to properly set up your barcode data.

Look at the number of unique products you stock, and figure out which barcode type can carry the information/attributes they possess:

- 1D barcodes (like UPC or EAN) are great for simple product identification.

- 2D barcodes (like QR codes or Data Matrix) can carry extra details like serial numbers or expiry dates—ideal for complex tracking needs.

Next, decide how you want to handle the tech side.

You can use dedicated barcoding software that plugs into your current IMS, or switch to an inventory system that comes with barcode functionality built in.

Pick whatever fits your budget and setup. Just make sure it matches the complexity of your inventory.

Organize your physical inventory for faster, cleaner counts

Tech and teamwork will get you far. But if you want to make those efforts sustainable, you’ve got to create a conducive environment… literally.

That means adjusting your warehouse or stockroom layout to support faster, cleaner reconciliation.

Start with the basics:

- Clear SKU labeling, so there’s no second-guessing what’s what

- Zone mapping to group products logically (by category, velocity, seasonality—whatever makes sense for your flow).

Keith Gorney, head of supply chain at Pivotree (frictionless commerce provider), provides a good example:

For warehouses, it’s smart to keep high velocity SKUs in back stock and forward pick locations.

These items typically have the highest number of discrepancies, so keeping them accessible supports quick cycle counts and inventory reconciliation.

If you own a retail space, the mirrored planogram approach could work well for you because you don’t have to memorize two layouts.

This strategy aligns your stockroom with what customers see in your shop.

The mirrored planogram reflects the flow of merchandising on the sales floor in the back room.

This helps to streamline picking, stocking, and reconciliation for team members, as the flow of work is natural between front of house and back of house.

Analyze root causes of recurring discrepancies

You already met the usual suspects, but in every business, one issue tends to stand out more than the rest: Human error.

Brian Lim, founder of brands like I Heart Raves and Into the AM, shares his perspective:

On top of the list sits human error. Staff failing to count the correct number of items, scanning barcodes incorrectly, and entering data wrong are all common in day-to-day operations.

He also explained that internal and external theft play a huge role, but how do you tell them apart? The trick is teaching your staff to go beyond the numbers.

Lim explained that infrequent inventory checks coupled with inadequate staff training often result in inventory discrepancies going undetected and unaddressed.

Finding the error is only step one. The bigger and more exciting step requires your team to put on their detective cap and uncover where the bad guy has slipped in.

For example, if certain discrepancies occur consistently during the same shift or in a specific storage area, it could indicate internal issues.

On the other hand, losses associated with high-theft items or shipping inconsistencies may be the result of external causes such as shoplifting or supplier-related shrinkage.

Therefore, he advises brands to:

Include training on inventory handling, data capturing, and identifying discrepancies such as damaged items or miscounts, and other irregularities.

Cultivate a sense of responsibility by designating inventory sections to individual team members.

Inventory reconciliation is so much more than matching numbers. Done right, it also helps nip any discrepancies in the bud moving forward.

Get your team’s buy-in

Your staff is your primary asset, according to Georgia Leybourne, CMO at Linnworks.

She believes that, “The key to staff orientation with inventory is to be fully transparent on what you’re trying to achieve, pitfalls you’ve come across and the impact on the business of various scenarios.”

Brian Lim (Into the AM) agrees, “Staff who understand the business impact of discrepancies are more invested in maintaining accuracy.”

Therefore:

Give them context and get them to buy-in to the criticality of inventory reconciliation. You’ll find they jump on board and help you take care of your second-biggest asset, your inventory.

That brings us all the way back to Tip #1: Nail your SOP.

If you have a solid one, getting your team up-to-speed won’t feel like herding cats. Explain the importance of inventory reconciliation for the company and them, as well.

Then dive into the specifics:

- The to-do’s. Provide live hands-on workshops. No dusty handbook or PDFs over emails, please.

- The go-to person. Assign clear roles. People in charge can also provide training and guidance.

- The tools. Show them how to use barcode scanners, mobile apps, or whatever tech you’ve implemented.

- The follow-up. Set up a 30-day follow-up to answer questions and reinforce habits.

When you pair education with empowerment, you can improve your inventory management processes and tighten up loss prevention strategies.

Track KPIs to monitor shrinkage and reconciliation performance

Metrics give you real, raw data to tell you how you're doing. If you want to gauge your reconciliation performance, here are some KPIs to keep tabs on:

- Inventory accuracy rate: How quickly is your inventory being sold and replaced? A high turnover rate reflects efficient inventory management. It means you’re not stuck with obsolete stock and discrepancies.

Inventory Accuracy = (Counted Items ÷ Items on Record) × 100

- Inventory turnover rate: What percentage of your inventory records are correct? It measures the precision of your inventory data, indicating that the tracking systems you have in place are doing a swell job!

Inventory Turnover Rate = Cost of Goods Sold (COGS) ÷ Average Inventory

- Shrinkage or shrink rate: What percentage of your inventory is unaccounted for? Stock shrinkage is the difference between actual stock and recorded inventory. If it’s high, you’ll need to tighten your inventory control processes or increase reconciliation frequency.

Shrinkage Rate = (Recorded Inventory − Actual Inventory) ÷ Recorded Inventory × 100

- Reconciliation accuracy: How often do your physical counts match your records? This KPI reflects the effectiveness of your reconciliation processes. It can tell you whether you need to tweak procedures or train your staff better.

Reconciliation Accuracy = Number of Accurate Counts ÷ Total Number of Counts × 100

- Cycle count coverage: What portion of your inventory is reviewed regularly? It assesses how much of your stock is included in periodic counts. A comprehensive coverage ensures discrepancies are identified and corrected promptly.

Cycle Count Coverage = Number of Items Cycle Counted ÷ Total Number of Items in Inventory × 100

Feel free to add other KPIs that suit your business better. What matters most will depend on your product types, order volume, and how often your inventory moves.

Make Your Inventory Reconciliation Strategy Count

Inventory reconciliation isn’t one-and-done. Your inventory is constantly in motion—products are being sold, returned, restocked, or damaged.

So long as you’re running your retail business, you need to get it right every time.

Performing inventory reconciliation on a regular basis keeps your records accurate, your stock levels healthy, and your team (and customers) satisfied. Skipping it can lead to errors piling up and profits slipping through the cracks.

Here are other relevant articles on inventory management that you can bookmark to level up your operations and stay ahead of stock issues:

- Just-in-Time Inventory (JIT): The Complete Guide to Responsive Operations

- Top 10 Inventory Management Challenges And How To Solve Them

- AI Inventory Management: How to Use Robots For Efficient Inventory Operations

- Consignment Inventory Explained: A Guide for Retail and Ecommerce Operators

- Cycle Inventory: What It Is, How To Calculate & Top Tools

- Inventory Carrying Costs Explained: Calculation & Reduction Strategies

Retail never stands still—and neither should you. Subscribe to our newsletter for the latest insights, strategies, and career resources from top retail leaders shaping the industry.

Inventory Reconciliation FAQs

Got more questions on inventory reconciliation? You might find the answers here.

What’s a “good” shrinkage rate for my retail business?

It will depend on your business, but according to FitSmallBusiness, a good shrinkage rate is between 1% and 2%.

Use our Shrinkage Calculator to determine yours and learn all about shrinkage in our guide.

Can reconciliation be fully automated? If so, what’s the tradeoff?

Yes, by integrating your systems (WMS, IMS, barcode scanning technology), it’s possible. However, you need human oversight to spot anomalies, analyze the trends, and put a stop to them.

How do I reconcile inventory across multiple store locations?

First, reconcile your inventory data with a centralized inventory management software. It will give you real-time stock level visibility as a whole, and at each site. Then arrange synchronized cycle counts and scheduled audits. The same holds true for multichannel inventory management.