Budget-Friendly Software Options Exist: Inventory management software costs range from $50/month to $500/month, offering flexible options suited to various budget levels.

The Average Cost Per Month: The typical average monthly expense for inventory management software is around $175.

Affordable for Beginners, Too: Even for new businesses with limited funds, there are inventory management software options that won't break the bank.

Wide Price Spectrum: Inventory software prices vary significantly, enabling businesses to find solutions that fit their specific financial capabilities.

$175/month. That’s the average cost of inventory management software. However, the range is quite extensive—from $50/month to $500+/month.

Investing in inventory software might sound unreasonable if you’re just starting a business and short on funds.

But if you zoom out, you’ll see that inventory management systems are the lifeblood of retail businesses. The question isn’t really if you need an inventory management system—you most certainly do—but how to determine if a system you’ve chosen is worth the price.

In this guide, we discuss factors that drive the prices of inventory management software and explain how to analyze the costs vs. benefits.

Factors That Determine Inventory Management System Costs

The total cost is a factor of multiple parameters. Let’s take a quick look at the cost drivers of an inventory management system:

- Software type (cloud-based vs on-premise): There’s a lot of difference of opinion here—some experts believe cloud-based solutions are cheaper, while others believe on-premise options cost less. For the majority of companies, cloud-based options (almost all of these are SaaS) are cheaper because they don’t need to replace the hardware.

- Number of users: Most inventory management solutions are priced per user per month. Some even have a plan-wise cap on users. For example, they may require you to upgrade once you hit a certain number of users.

- Number of locations: Some providers, especially ones that offer on-premise solutions, may charge for each location or device you’re using the software on. With cloud-based services, you can just add more users and upgrade your plan if and when necessary.

- Modules and add-ons: Modules and add-ons are a great way to extend the software’s functionality. The exact cost depends on the type of module or add-on.

- Features and functionality: Solutions with advanced inventory management features cost more. Many providers offer basic features on the lower tiers and advanced features like RFID tracking and automated reordering on the more expensive plans. This is a great option if you’re a startup because you can always unlock advanced features as you grow.

- Barcode scanning capabilities: Inventory management software with barcode scanning capabilities is generally more expensive.

- Customization requirements: If your business needs are complex enough to warrant customization, you may have to spend extra. The cost of customization can vary depending on the complexity of your needs.

- Integration with other systems: The inventory management solution must integrate with your CRM, ERP, and other systems if you plan to automate your workflow. The software must also integrate with the ecommerce platform you’re using, such as Shopify, Amazon, or WooCommerce. Tools that offer out-of-the-box integrations typically cost more, but it’s worth the cost.

- API access: API access gives you the ability to integrate with systems for which the provider doesn’t offer out-of-the-box integrations. It’s an excellent feature but does cost extra.

- Customer support options: Email support can be slow. If you don’t want to wait 24 to 72 hours for a support agent to get to your case, look for tools that offer live chat and phone support. These options tend to cost more, but are ideal if you need instant help.

- Implementation and training: Expect to pay extra if you need the provider to help implement the software and train your team. Unless you have an expert on the team, it’s definitely worth investing in implementation and training.

- Scalability and future growth: Systems that can support fast-paced growth generally cost more. Cheaper solutions may fail to keep up with growing business needs, especially when business is growing quickly.

While it’s typically not too difficult to compute these costs, things can get tricky if inventory management features are part of a more comprehensive system, such as a warehouse management system, accounting/inventory software, or supply chain management software.

Types of Inventory Management Software

Now that you've got a handle on the cost drivers, let’s quickly cover the different "flavors" of inventory management software you'll encounter. Understanding these categories will help you better align your choice with your budget and operational goals.

- Standalone systems. These are purpose-built inventory management tools designed to handle core inventory functions—tracking, counting, reordering, and basic reporting. They tend to have simpler user interfaces, lower setup costs, and shorter implementation times. Ideal if your main pain point is pure inventory management, and you don't need all the bells and whistles.

- Integrated suites. These systems bundle inventory management as a module within a broader ERP (enterprise resource planning), POS (point-of-sale), or CRM (customer relationship management) platform. They're pricier upfront, but the payoff is a fully unified system. Data flows seamlessly across departments, which streamlines operations and reduces headaches from connecting multiple tools.

- Cloud-based (SaaS) vs on-premise. This choice significantly impacts both upfront and ongoing costs:

| Cloud-based inventory software (SaaS) | On-premise inventory software |

|---|---|

| Pricing model: Monthly subscription fee. Predictable, lower upfront costs. | Pricing model: One-time licensing fee. Higher upfront investment. |

| Hardware: None required (web-based). | Hardware: Servers, devices, and infrastructure required. |

| Maintenance: Handled by vendor, minimal IT overhead. | Maintenance: Your team manages updates, security patches, and hardware maintenance. |

| Scalability: Easily scale users/features up or down. | Scalability: Limited by your internal hardware and IT resources. |

| Best for: Smaller businesses, rapid scaling, minimal IT involvement. | Best for: Larger businesses, stable inventory requirements, in-house IT teams. |

Clearly understanding these options helps you pick an inventory management solution that genuinely fits—not just your budget, but your operational reality as well.

Inventory Management Software Pricing Comparison

In this section, we look at the common plan types and compare the prices of the best inventory management software solutions on the market.

Inventory management plan type comparison

Every tool has its own unique pricing structure. However, here’s a general overview of what these pricing tiers might look like:

| Plan Type | Average Price | Common Features Included | Best For |

|---|---|---|---|

| Free | $0 | - Basic inventory management - Limited orders per month - Community support - Essential features only | Startups and very small businesses |

| Basic | $0 - $50/month | - Real-time inventory tracking - Basic reporting and analytics - Single user access - Limited SKUs and transactions | Small businesses |

| Standard | $50 - $150/month | - Multi-location tracking - Barcode scanning - Multi-user access - Advanced reporting - Integration with other business tools | Growing small to medium-sized businesses |

| Premium | $150 - $500/month | - Full feature access - Custom integrations - Unlimited SKUs and transactions - Advanced analytics and forecasting - Dedicated support | Medium to large businesses |

| Enterprise | $500+/month (or custom pricing) | - Customizable features and workflows - API access for custom integrations - Personalized onboarding and training - Priority support - Scalability options for large businesses | Large enterprises |

Inventory software needs vary by industry:

Depending on your business type, you'll have unique inventory management requirements that can affect which features—and plans—you'll need. For example:

- Manufacturing: Bill-of-materials tracking, serial number management, and real-time monitoring of work-in-progress (WIP).

- Hospitality and foodservice: Inventory tied to recipes, shelf-life management, and allergen tagging.

- Pharmaceuticals and electronics: Robust lot and batch tracking, expiry-date alerts, cold-chain compliance, and detailed audit trails.

Keep these industry-specific needs in mind when comparing costs and selecting your software.

Compare pricing for our top inventory management software picks

Selecting the right tool makes a world of difference in how effectively you’re able to manage inventory.

We did some leg work to make things easy for you—below is a price comparison of the top inventory management systems on the market:

Hidden IMS Costs To Consider When Choosing

Don’t assume the price tag you see on the pricing page is what you’ll pay. Generally, there are additional costs that you might not see on this page.

While this isn’t always the case, it’s best to keep your eyes wide open when selecting an inventory system.

Let’s talk about the types of hidden costs you should watch out for.

- Setup and implementation fees: The cost of setting up your inventory management system includes the cost of configuration, customization, and hardware setup, among other things. The service provider may also charge an implementation fee to help you set everything up.

- Training costs: Training costs are directly proportional to the system’s complexity. More complex systems require more training hours, which translates to higher training costs.

- Data migration fees: Importing data can be a lengthy process, especially when dealing with a legacy system. The vendor or an IT service provider can take care of the migration for a fee.

- Maintenance and upgrade costs: Maintenance costs include maintenance for software as well as hardware. Software updates and security patches are often included in the price, but hardware maintenance for devices like barcode scanners and printers is extra. The vendor might even charge extra for feature upgrades or customization enhancements.

- Add-on modules and features: Some providers may offer add-on modules to complement the system’s feature set. Add-ons offer a quick way to access add-ons, but make sure you buy software that meets your needs so you don’t overspend on add-ons.

- Support costs: Basic email support usually comes included, but quicker response times, live chat, dedicated phone support, or assigned account managers typically incur extra charges. Premium support tiers can easily increase your monthly fees by 10–30% or more, so clarify these costs upfront.

- Consulting and advisory services: You may have to pay consulting fees to the provider or an external consultant if you need advice on the best ways to deploy a specific feature or the system as a whole.

- Integration costs: Ready-to-use integrations may be included in the price or cost extra, depending on your plan and vendor. But if you want to use APIs to integrate systems, you’ll likely have to spend extra, and this can add up to your total cost.

Common Pitfalls of Inventory Management Software

You’ve seen the hidden costs to watch for—but even when you budget carefully, there are practical challenges that can derail your investment if you don’t plan ahead.

Choosing inventory software isn’t just about price or features—it’s about making sure it really works for you in the long run.

- Data accuracy and adoption problems. Bad data imports, inconsistent entries, or team resistance can undermine your system’s accuracy and wipe out potential ROI.

- Integration headaches. Even with good APIs or out-of-the-box connectors, syncing with your POS, ERP, or ecommerce systems often reveals hidden complexity and surprise costs.

- Scalability surprises. A plan that’s perfect for 500 SKUs might struggle at 50,000 if it isn’t designed to scale smoothly.

- Ongoing management burden. Implementation isn’t the finish line. Expect regular maintenance, employee training refreshers, and admin time to adapt the system as your business evolves.

Knowing these pitfalls helps you set realistic expectations—and prepares you to perform a thorough, meaningful cost-benefit analysis next.

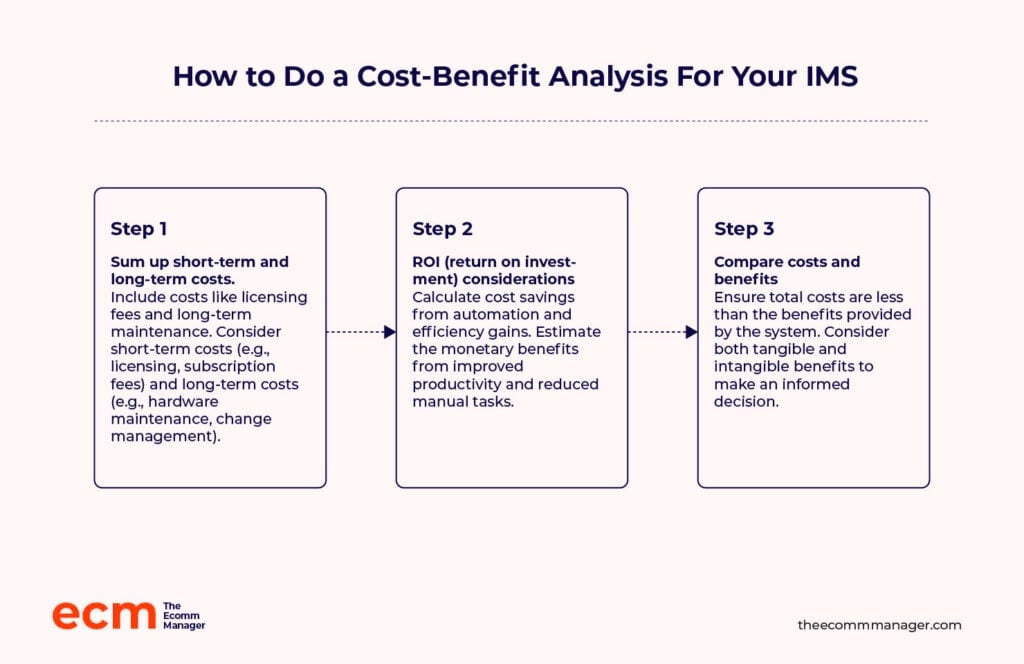

How To Do A Cost-Benefit Analysis For Your IMS

43% of small businesses in the U.S. don’t track their inventory at all. While some companies aren’t fully aware of inventory management systems, many are hesitant to take on recurring expenses.

It’s a logical but incomplete argument—if you choose the right software and use it tactfully, inventory management systems can generate a great ROI.

To estimate if your investment will be ROI-positive in the long run, try to value the benefits you expect to derive from the inventory management system and do a cost-benefit analysis.

This can help you feel more confident about the relationship between your investment in software and its impact on profitability.

Allow me to walk you through the process.

Step 1: Sum up short-term and long-term costs

Short-term costs like licensing and subscription fees are fairly clear because you pay them when you buy the software or shortly after.

But long-term costs like regular maintenance of hardware components (scanners, printers, and mobile devices) and change management to help employees adapt to new technologies like AI and ML become clearer as you go.

And that’s the tricky part.

There’s no definitive method to calculate these costs, so estimate them based on probabilities and prevailing trends.

What you need is a number that represents the total cost (short- and long-term) of using the software over the next 10, 15, or 20 years, depending on the time frame of your analysis.

Step 2: ROI (return on investment) considerations

Once you know the costs, let’s talk about the weight on the other side of the seesaw—the benefits. Of course, we want a value for these benefits, not a list.

Cost savings from automation and streamlining processes

Inventory management systems streamline your workflow, automate mundane tasks, and make your best employees more productive.

Grab a calculator and try to estimate the amount of money you’ll save when your employee doesn’t spend time recording the inventory when it arrives at the warehouse, is moved to a different location, and is sold.

Suppose you pay an employee $3,200 a month to record inventory-related transactions.

They work 40 hours a week or 160 hours a month. After implementing inventory management software, they save 40 hours each month.

That translates to savings of $800/month.

During these hours, the employee can focus on renegotiating vendor contracts based on seasonal trends or building a better inventory workflow to maximize efficiency.

Speaking of efficiency…

Efficiency and productivity gains

Inventory management software automates almost every part of your workflow. This helps you function more efficiently and productively.

Think about it—inventory management software can automate communication with suppliers for order confirmations, shipment tracking, and invoice management.

Your team never has to intervene.

Top software solutions also offer an analytics dashboard that helps you track KPIs and inventory performance in real time and generate comprehensive reports on inventory turnover, stock aging, and sales trends.

Many systems offer a mobile app for Android and iOS devices. A mobile app allows you and your team to view inventory and order status regardless of where you are.

If you’re in an industry where traceability is important for compliance, such as food, pharmaceuticals, or electronics, look for built-in inventory tracking and order management features.

This will ensure that you never have to look too far to identify the source or current status of inventory items or finished products.

Of course, this also saves you plenty of time you’d otherwise spend manually tracking inventory.

Impact on inventory control and stock levels

Inventory management systems offer complete control over inventory. It provides you with real-time visibility of stock levels and has built-in reorder reminders.

And this can unlock substantial business value—McKinsey reveals that US retailers are sitting on $740 billion of unsold goods.

Modern systems can even place an automated order when inventory levels dip below the safety stock level. But there are quite a few things that happen on the backend before these numbers reflect on your system.

For example, a sale is recorded when the customer checks out via your store or the product’s barcode is scanned at your brick-and-mortar.

Similarly, the system uses preconfigured rules to place an order when a product’s inventory breaches the safety stock level.

These rules include:

- The approved vendor to place the order with

- The agreed-upon price or price range

- Lead time as per the contract

- Information necessary to calculate the economic order quantity (EOQ), including the ordering and holding cost

Some inventory management solutions include various additional features to give you even more control over inventory.

However, remember that you don't need every feature ever built—when choosing inventory management software requirements, focus on features like bill of materials that are meant for manufacturers, not retailers.

For example, some tools include a built-in demand forecasting tool. They automatically request a readjustment of the safety stock level based on seasonal trends.

Subject to your subscription plan, you might be provided access to a customizable KPI dashboard where you can track metrics like inventory turnover, carrying cost of inventory, and order cycle time.

The way to value these benefits? A simple what-if analysis.

Sum up your current costs that would have been avoidable if you had access to real-time inventory data, KPIs, and a more statistical idea about the inventory you should hold. The costs you add here can include the carrying cost of inventory and the cost of stockouts.

And that’s the value of the benefits.

Step 3: Compare Costs and Benefits

The total cost of using the inventory management system, including the stated price and hidden costs, should be less than the value that the system offers.

Okay, that’s not rocket science. But here are three things you should know:

- Don’t forget about other factors: Just because the inventory management system saves your record keeper 15 hours a week doesn’t mean they’re determined to put those hours to good use. You still need great employees and a terrific work ethic to realize the value of inventory management software.

- The benefits generally outweigh the costs: You can save plenty of money using inventory management software if you play your cards right. It’s a powerful tool that can help you differentiate customer experience and allow your team to focus on strategic decisions.

- A cash flow problem is a good reason to be skeptical: Spending on an inventory management tool may be counterintuitive if you’re strapped for cash. But it’s best to at least use a free inventory management system so you have access to basic features like real-time inventory updates and automated reorder points.

Looking Ahead: Recent Trends in Inventory Management Software

As you evaluate costs and features, it also pays to know where the industry is heading. These developments are shaping what inventory software can do—and what you'll need to budget for as expectations rise:

- AI-driven automation. Systems are adding smarter demand forecasting, automated reorder point adjustments, and predictive stock insights to cut human error and stockouts.

- Sustainability features. Many vendors now include tools for tracking carbon footprint, reducing packaging waste, and optimizing delivery routes to support greener operations.

- Hyper-automation and integration. Expect increasingly seamless connections with ERP, ecommerce, and logistics systems—complete with workflows that automatically reorder, transfer, and balance stock.

- Mobile-first interfaces. More providers are prioritizing intuitive mobile apps and handheld scanning to make inventory management truly accessible anywhere.

Keeping these trends in mind helps you choose software that won’t feel outdated in a year or two—and ensures your investment can evolve with your business.

Inventory Management Software Is Table Stakes, Not A Competitive Edge

While inventory management software might make you feel great about your newfound control over your inventory, remember that almost all your competitors are probably using one as well.

It’s not a magic wand that solves inventory problems. You still need great vendors, favorable terms with vendors, and physical security over inventory for successful inventory management.

If you do want to use inventory management software to gain a competitive edge, you can do this by:

- Using the demand forecasts offered by the system as a starting point for your own forecasts

- Tracking and monitoring KPIs to ensure you’re always practicing financial prudence when making inventory-related decisions

- Ensuring that all team members understand how to make the best use of an inventory management system

Like what you just read? Sign up for The Retail Exec newsletter to receive expert insights and the latest trends in ecommerce in your mailbox.