The Hidden Hero of Ecommerce: Inventory management is crucial to ecommerce success, affecting everything from cash flow to customer satisfaction. Poor inventory systems cost retailers $818 billion last year, highlighting the need for efficient inventory control.

Avoid the Spreadsheet Spiral of Doom: Managing inventory with disconnected spreadsheets leads to inaccuracy and inefficiency. Investing in real-time, integrated systems prevents costly stockouts, overstocks, and improves overall business operations.

Predicting Demand is Not Magic: Relying solely on historical sales data for forecasting is insufficient. Incorporating variables like marketing events and seasonal trends can improve demand prediction and inventory management accuracy.

The Real-Time Rescue: Centralizing inventory data with automated, real-time systems reduces errors and enhances operational efficiency. Continuous tracking ensures accurate fulfillment, reducing revenue loss and increasing customer trust.

Unseen Inventory Loss: Inventory loss occurs through spoilage, damage, and obsolescence. Monitoring loss as a separate metric and implementing preventive measures helps minimize its impact on margins and inventory accuracy.

Inventory might not be glamorous—but in ecommerce, it’s make or break. A single error can snowball into overstocks, stockouts, lost revenue, and unhappy customers.

And yet, too many businesses are still managing inventory with siloed systems, disconnected spreadsheets, and manual processes that leave them flying blind. For solutions, consider these inventory management improvements.

Here’s the kicker: retailers lost a staggering $818 billion last year to inventory distortion—52% from stockouts, 44% from overstocks.

These aren’t small slip-ups. They’re systemic breakdowns that throttle cash flow, disrupt order fulfillment, and crush customer satisfaction.

I’ve seen this mess firsthand.

Before diving into ecommerce strategy, I spent years as an inventory controller and later a warehouse manager—managing inventory accuracy, cycle counting, reconciling discrepancies, and optimizing warehouse workflows.

If there’s a tracking issue, a loss problem, or a broken process hiding in your warehouse, I’ve probably wrestled with it.

Why does this matter so much? Because inventory is one of the few levers that touches every part of your ecommerce operation—from procurement to pricing to the post-purchase experience.

When inventory is off, your supply chain slows, your storage space clogs up, and your margins take the hit. When it’s dialed in, you can fulfill faster, forecast smarter, and free up capital for growth.

In this guide, I’m breaking down the most common inventory management challenges holding ecommerce teams back—from demand forecasting failures to warehouse inefficiencies—and offering up real-world strategies (plus some hard truths) to help you fix them.

Why Inventory Management is the Backbone of Ecommerce

Inventory management isn’t just a back-office function—it’s the nerve center of your ecommerce operation.

When it's dialed in, you fulfill faster, forecast smarter, and scale without tripping over your own supply chain.

When it's not? You bleed revenue from stockouts, lose customers over missed deliveries, and bury capital in excess inventory.

Whether you're using ERP software, a lean inventory system, or even spreadsheets (no judgment—I've been there), the mission stays the same: accurate inventory, satisfied customers, healthy margins.

And the payoff is real.

Companies with high-performing inventory management processes are 79% more likely to grow revenue faster than the industry average.

As someone who's been there, I’ve seen the power of great inventory control—and the chaos of poor tracking. This stuff isn’t just about numbers. It’s about unlocking cash flow, tightening workflows, and delivering consistently, even under pressure.

Inventory management doesn’t just support ecommerce growth. It drives it. Discover the benefits of inventory management software to enhance your operations.

12 Top Inventory Management Challenges (And How to Solve Them)

No matter how sharp your ecommerce strategy is, inventory problems have a way of sneaking in—and compounding fast.

From mismatched data to warehouse slowdowns, these aren’t just operational headaches. They’re margin killers.

And while the root issues might look different—manual tracking, lack of real-time data, inaccurate forecasting—they often lead to the same outcomes: lost sales, frustrated customers, and wasted capital.

Based on years in the trenches (plus a whole lot of cycle counts and discrepancy reports), here are the biggest inventory management challenges I’ve seen—and the practical fixes that actually work.

1. Balancing stock levels: Overstocking vs stockouts

One of the most persistent problems in inventory management is imbalance.

Overstocking locks up capital and consumes valuable warehouse space. Stockouts lead to missed revenue, backorders, and lost customer trust. Both are costly—and often, both are happening at the same time.

The core issue? Inaccurate inventory data and poor demand visibility.

Many operations rely on inconsistent tracking methods, fragmented systems, or spreadsheets that can't keep pace with real-time fluctuations in demand, making open source inventory solutions an attractive alternative.

When replenishment is based on outdated numbers or gut feel, you're left reacting instead of planning. Implementing cross-docking solutions can aid in smoother inventory flow and better planning.

| Inventory issue | Impact on operations | Financial consequence |

|---|---|---|

| Overstocking | Ties up storage space, slows movement | High carrying costs, cash flow drag |

| Stockouts | Delays fulfillment, kills CX | Missed revenue, loss of loyalty |

| Inaccurate tracking | Reorders misaligned with demand | Compound errors, inefficient restocking |

Solutions that work

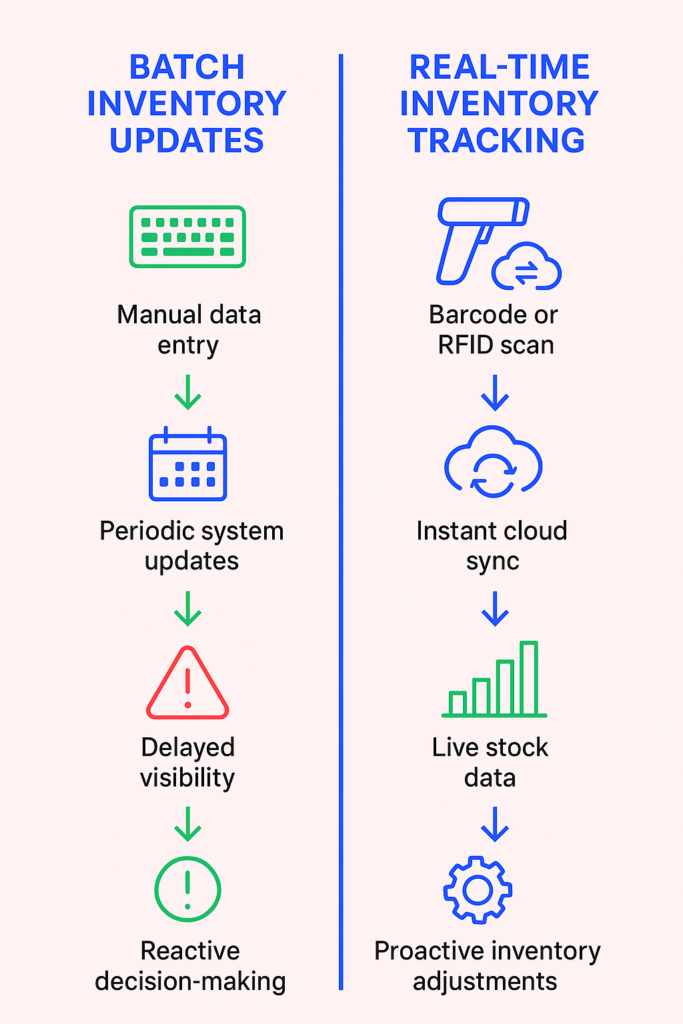

- Get accurate, real-time data. Switch from manual tracking or periodic updates to systems that reflect inventory movements as they happen. Tools with barcode or RFID integrations make this seamless.

- Forecast with context, not just history. Historical sales are useful, but incomplete. Layer in marketing calendars, seasonal trends, and supplier lead times to build a more complete demand picture.

- Automate dynamic reorder points. Rigid stock thresholds don’t work in a volatile environment. Use inventory software that adapts reorder points based on current velocity, not static rules.

- Triage fast movers. High-demand products need closer monitoring and more responsive restocking strategies. Low-risk items can follow steadier replenishment cycles.

- Tighten process discipline. Even with great software, inaccurate data entry or skipped cycle counts will throw your numbers off. Standardize inventory workflows and audit regularly.

Inventory balance isn’t about perfection. It’s about consistency, visibility, and making smarter decisions with better inputs.

2. Forecasting accuracy: Getting demand right before it's wrong

Forecasting isn't just about guessing what customers might want—it's about making high-stakes decisions on procurement, cash flow, and fulfillment.

And when the inputs are off, everything downstream suffers.

The challenge is that demand isn’t static. Promotions, seasonality, supply chain delays, and shifting consumer habits all make it harder to predict what inventory levels should look like in two weeks, let alone next quarter.

Most teams lean too heavily on historical sales data without adjusting for real-world variables.

The result? Either shelves full of the wrong products or stockouts of the right ones.

Solutions that work

- Use forecasting models that learn. Move beyond basic spreadsheets. Forecasting tools that apply machine learning can weigh variables like seasonality, recent trends, and marketing events to improve over time.

- Break down demand by channel. Forecasting in aggregate hides problems. Segmenting by channel (e.g. DTC vs wholesale) gives you more control over how you allocate stock.

- Build buffers based on risk, not rules. Fixed safety stock formulas don’t reflect actual volatility. Use performance history and supplier reliability to decide where you need extra coverage.

- Work closely with sales and marketing. It’s not just about algorithms. Your sales team knows what’s coming down the pipeline; marketing knows what’s about to spike demand. Forecasting gets smarter when teams stop working in silos.

- Revisit your forecast regularly. A forecast isn’t a one-and-done exercise. Review it often—weekly, if needed—and adjust based on what's actually happening in your systems and on the ground.

Forecasting doesn’t have to be perfect. But it does have to be proactive. And in a high-velocity ecommerce environment, static models just won’t cut it.

Forecasts don’t fail—your network does. Multi-echelon inventory optimization makes sure the insights actually land.

3. Real-time tracking: Knowing what’s where (and when)

Without real-time tracking, you’re always a few steps behind.

You can't fulfill orders efficiently, plan replenishment accurately, or catch discrepancies before they snowball.

The problem is often rooted in fragmented systems. Inventory data might live in multiple platforms—warehouse software, sales channels, supplier portals—none of which sync reliably or update in real time.

Manual data entry adds more delays and opens the door to human error.

For high-value or perishable goods, even small tracking gaps can lead to major losses in both revenue and trust.

Solutions that work

- Centralize your inventory data. Use an inventory management system that acts as a single source of truth, connecting your warehouse, sales channels, and fulfillment ops in one place.

- Automate movement tracking. Barcode scanning, RFID tags, or IoT sensors can drastically improve location accuracy and update inventory counts in real time.

- Eliminate batch updates. Sync inventory movement automatically, not through manual CSV uploads or once-a-day refreshes. Real-time tracking only works if the system is truly live.

- Train for consistency. The best systems still rely on people to follow process. Build clear SOPs for receiving, transfers, and cycle counts—and make sure they’re followed.

- Audit high-risk inventory more often. If you know certain SKUs or storage locations are more error-prone, check them frequently. Real-time systems help, but spot checks keep everyone honest.

If you can’t trust your inventory numbers minute to minute, you’re gambling with fulfillment speed and customer experience. Real-time visibility is the baseline—especially as ecommerce expectations keep climbing.

Overcome inventory management challenges by implementing a perpetual inventory system that offers real-time solutions to common issues.

4. Inventory visibility: Connecting the dots across your supply chain

Lack of visibility is one of the most common—and most expensive—inventory problems in ecommerce.

You might know what’s in your main warehouse, but what about returns in transit? Or inbound stock that hasn’t been checked in? Or inventory sitting with a third-party logistics partner across the country?

Without a clear, unified view of inventory across all locations and stages, fulfillment slows down, overselling happens, and customers end up getting disappointed.

The issue usually stems from disconnected systems, incomplete data, or inconsistent processes for tracking inventory as it moves.

Visibility gaps don’t just create errors—they delay every decision you make.

Solutions that work

- Use a system with multi-location visibility. Your inventory management software should give you a single dashboard showing on-hand, in-transit, and reserved inventory—across every node in your supply chain.

- Integrate with your ERP or WMS. Inventory data shouldn't live in silos. Sync your inventory system with your ERP or warehouse management system so everyone’s working off the same numbers.

- Tag and track inventory at every stage. Use RFID or barcode scanning to track SKUs through receiving, putaway, picking, and shipping. No gaps, no guesswork.

- Document movement consistently. Incomplete or skipped entries lead to phantom stock and false availability. Build clear documentation protocols and audit them regularly.

- Monitor exceptions, not just quantities. Visibility isn’t just about knowing how many units you have. It’s about flagging discrepancies, delays, or mismatches before they become fulfillment problems.

You can’t manage what you can’t see. And in modern ecommerce, partial visibility is as risky as no visibility at all.

5. Supply chain disruptions: Preparing for what you can’t predict

You don’t need a global crisis to feel the sting of a supply chain disruption. A late container, a raw materials delay, or a supplier shutdown can stall your entire operation.

The problem isn’t just the disruption—it’s how exposed your inventory systems are to even small breakdowns.

When everything is optimized for speed or minimal stock, there’s no cushion. Lead times stretch, safety stock disappears, and your ability to fulfill orders on time takes a hit.

These ripple effects often reveal bigger cracks: over-reliance on single suppliers, rigid procurement workflows, or a lack of real-time visibility into what’s inbound and when.

Solutions that work

- Diversify your supplier base. If one partner stalls, you need a fallback. Build redundancy into key SKUs, especially for high-margin or high-volume items.

- Use inbound tracking tools. Don’t just wait for shipments—track them. Integrate supplier portals or logistics visibility platforms so you know what’s delayed and why.

- Layer in dynamic safety stock. Instead of using a fixed number, calculate safety stock based on lead time variability and demand volatility. This gives you real buffer, not guesswork.

- Build flexibility into procurement. Locking into long contracts or static MOQs can backfire when conditions shift. Negotiate for flexibility where you can.

- Run scenario planning regularly. Map out what happens if a key supplier drops or shipping lanes back up. These aren’t hypotheticals—they’re prep work.

Disruptions will happen. The goal isn’t to avoid them entirely—it’s to make sure they don’t catch your business flat-footed.

Supply chain disruptions are inevitable, but being blindsided by them isn't. Equip your operations with container tracking software to gain real-time visibility and stay ahead of delays.

6. Inventory loss and obsolescence: What’s vanishing from your books (and your shelves)

Inventory doesn’t just disappear through sales. It spoils, breaks, gets misplaced, or sits untouched until it becomes obsolete.

These losses chip away at margins quietly—and often go untracked until they show up as a line item in your write-offs.

Obsolete inventory is a particular pain point.

Maybe demand dried up. Maybe the product version changed. Or maybe it just got buried in the back of the warehouse.

However it happens, excess stock that no longer moves is tying up capital, space, and attention that should be going to faster-moving items.

And while it’s easy to chalk this up to bad luck or market shifts, most of these problems trace back to preventable process gaps—lack of SKU visibility, inconsistent cycle counts, poor stock rotation, or missing data on expiry or shelf life.

Solutions that work

- Track loss as its own metric. Don’t lump it into “inventory adjustments.” Break out shrinkage, damage, spoilage, and obsolescence so you can actually fix the root cause.

- Run aging reports monthly. Any SKU that hasn’t moved in 60–90 days needs to be reviewed. Flag stale stock early, long before it becomes unsellable.

- Use FIFO or lot tracking for perishable goods. First-in, first-out should be the default. For anything with a shelf life or regulatory pressure, lot tracking makes it enforceable.

- Automate cycle counts. Spot-checking high-value or fast-moving SKUs helps you surface loss patterns early. Don’t wait for year-end audits to find problems.

- Tie reordering to velocity, not gut feel. Obsolete inventory is often the result of over-ordering based on outdated assumptions. Let your data—not your instincts—drive replenishment decisions.

- Liquidate strategically. Don’t let dead stock drag. Run bundles, flash sales, or partner with off-price marketplaces to move slow inventory before it hits zero value.

Obsolete inventory isn't just "old stuff." It's inventory you can't sell—and that's the most expensive inventory of all. Proper stock rotation strategies can prevent products from becoming deadweight.

7. SKU proliferation: When product variety turns into operational chaos

Expanding your product catalog is usually a sign of growth—more styles, more bundles, more variations.

But with that comes more SKUs to manage, store, forecast, and fulfill.

When SKU count grows faster than your systems or processes can handle, accuracy drops and complexity spikes.

Cycle counting slows down. Inventory errors multiply. Reorder points get fuzzy. And warehouse teams spend more time finding items than shipping them.

Worse, not all SKUs pull their weight. A bloated catalog often hides low-velocity or redundant products that drain resources without adding value.

Solutions that work

- Run a SKU performance audit. Identify slow-moving or low-margin SKUs that aren’t justifying their shelf space. Cut or consolidate where it makes sense.

- Group variations where possible. Consider rolling up similar SKUs (e.g., size or color variants) under a parent SKU or style code to simplify tracking and reporting.

- Segment inventory handling. Fast movers need tight tracking and priority placement. Slow movers don’t. Build tiered inventory strategies based on SKU velocity and margin.

- Limit bundle complexity. Kits and bundles are great for AOV, but every new bundle is also a new SKU. Use virtual bundling (where the system assembles kits on the fly) to reduce overhead.

- Align with sales and marketing. Don’t let SKU creep happen in a vacuum. Make sure every new product added to the catalog has a clear commercial case and fulfillment plan.

- Set SKU creation rules. Who can create new SKUs? How are they named, tracked, and phased out? Codify it. Don’t let product growth create operational debt.

More SKUs isn’t always better. The goal isn’t maximum variety—it’s maximum clarity and control.

8. Cost management: Controlling what inventory actually costs you

Inventory doesn’t just cost what you pay your suppliers. There’s storage. Handling. Shipping. Returns. Obsolescence. Insurance.

Even the cost of capital tied up in unsold goods. And if you're not measuring these expenses, you're likely underestimating the true cost of your inventory decisions.

As businesses scale, these costs don’t just grow—they compound.

Inefficient picking processes, overordering, and unused warehouse space all start eating into your margins. And without the right systems in place, these leaks can go unnoticed for months.

Solutions that work

- Track total landed cost, not just unit price. Include shipping, tariffs, and handling so you can compare suppliers and SKUs accurately.

- Use ABC analysis to prioritize resources. Not all inventory should be treated equally. Focus optimization efforts on A-level items (high value, high velocity) where costs hit hardest.

- Reevaluate warehouse layout and workflows. Poor slotting and inefficient picking routes create unnecessary labor costs. A good warehouse management system can help rebalance it.

- Automate where ROI is clear. Automating label printing, pick lists, or reorder triggers can reduce manual errors and labor hours—without requiring a full robotics setup.

- Negotiate smarter, not just cheaper. Lower per-unit prices can come with higher lead times or inconsistent fill rates. Weigh short-term savings against long-term fulfillment reliability.

- Monitor carrying costs monthly. This includes storage, shrinkage, insurance, and depreciation. Regular reviews help flag inefficiencies before they become financial strain.

Cost management isn’t just about spending less—it’s about spending smarter, especially as inventory becomes more complex.

9. Seasonal demand variation: Staying agile when demand surges—or vanishes

Seasonal spikes are great for revenue—but brutal for inventory planning.

One wrong move and you're either sitting on dead stock after the rush or scrambling to restock while carts go abandoned.

The challenge isn’t just timing. It’s volatility.

Sales aren’t always consistent year-over-year, marketing calendars shift, and external factors (weather, shipping delays, economic dips) throw off even the best plans.

And yet many teams still use static forecasts or reorder models that don’t account for seasonality at all.

Solutions that work

- Segment your forecasting models. Seasonal SKUs shouldn’t follow the same logic as evergreen ones. Use separate forecasting rules for each product type or category.

- Build surge capacity into your ops. If you can’t flex your warehouse labor or fulfillment volume during peak weeks, you’ll hit a wall. Temporary 3PL support or flexible staffing can be a smart buffer.

- Plan for promotional spikes separately. Don’t let Q4 or sales events distort your “normal” baseline forecasts. Run promo-influenced demand models in their own lane.

- Time inventory receipts tightly. If your lead times are long, plan arrivals to hit right before the ramp—not weeks early. That reduces your holding costs while still ensuring coverage.

- Use post-season reports to tighten next year’s plan. Don’t just react. Review last season’s sales vs forecast, stockouts, markdowns, and returns. That data is gold for next season’s strategy.

Seasonal demand doesn’t have to feel chaotic. With tighter modeling and operational flex points, you can maximize sales without overcommitting inventory or warehouse space.

10. Compliance and regulations: Meeting standards without slowing down operations

Inventory management doesn't just have to be efficient—it has to be compliant.

And for industries like food, pharma, cosmetics, and regulated goods, the requirements aren't optional.

From proper labeling and lot tracking to temperature controls, expiry monitoring, and documentation protocols, regulatory compliance adds an extra layer of complexity that most inventory systems weren’t built for out of the box.

The problem isn’t just missing a rule—it’s failing to prove that you followed it. That’s where disconnected systems and manual processes become liabilities.

Solutions that work

- Use inventory software with compliance tracking built in. Lot numbers, expiry dates, audit logs, and chain of custody details should be automated and accessible.

- Map out industry-specific requirements. Don’t rely on general best practices—know the regulations tied to your product category and geography, and build them into your workflows.

- Automate documentation. Manual logs are slow and error-prone. Digital records reduce risk and make audits easier.

- Schedule internal audits before you’re required to. Spot-checking inventory documentation, labeling, and storage conditions helps you catch problems before they turn into violations.

- Train beyond warehouse staff. Compliance is a cross-functional issue. Everyone involved in product movement—from procurement to customer service—needs to understand the basics.

Regulations are only getting stricter. But building compliance into your inventory workflows upfront is a lot easier than trying to retrofit it after an inspection.

11. Manual documentation: Why spreadsheets still break your system

Many ecommerce teams still rely on spreadsheets, paper logs, or disconnected systems to track inventory changes.

It works—until it doesn’t.

Manual documentation creates delays, introduces human error, and leaves critical data vulnerable to loss or misinterpretation. There's no version control, no real-time syncing, and no easy way to scale.

What starts as a stopgap becomes a long-term drag on accuracy and efficiency.

And when the system breaks down? You're stuck playing detective with last month’s Excel file while orders back up and discrepancies pile up.

| Feature | Manual process | Automated system |

|---|---|---|

| Data accuracy | Inconsistent | High, real-time |

| Time to update inventory | Hours or days | Instant |

| Scalability | Low | High |

| Error tracking | Manual review only | Audit logs, alerts |

| Labor cost | High | Reduced |

Solutions that work

- Replace spreadsheets with real inventory systems. Even a lightweight cloud-based inventory tool is a massive upgrade over Excel. Look for options with barcode scanning, real-time syncing, and audit logs.

- Standardize all documentation. If you must use manual processes temporarily, define how data is entered, stored, and reviewed to reduce inconsistencies.

- Train for precision. Sloppy data entry leads to sloppy decisions. Make documentation accuracy part of your warehouse KPIs.

- Automate recurring tasks. Reorder points, receiving logs, and adjustments should be system-driven, not manually keyed in.

Manual tracking isn’t just inefficient—it’s risky. And in fast-moving ecommerce, those risks add up quickly.

12. Warehouse inefficiency: The hidden cost of poor workflows

You can have the right products, in the right quantities—and still lose time, money, and customers if your warehouse workflows aren’t dialed in.

Slow receiving, disorganized shelves, inconsistent picking processes, and lack of space optimization all contribute to lost labor hours and fulfillment delays.

And when workers have to spend time searching for items or redoing tasks, your per-order cost quietly climbs.

Warehouse inefficiency is often overlooked in favor of tech upgrades. But no system can fix broken physical processes.

Solutions that work

- Slot fast-moving SKUs in high-access zones. Minimize travel time by placing top sellers near packing stations or main aisles.

- Review picking methods. Batch picking, zone picking, or wave picking—choose the model that suits your order volume and SKU diversity.

- Optimize receiving processes. Clear procedures for checking in, labeling, and storing new stock reduce delays and errors.

- Use WMS tools with real-time location tracking. Knowing exactly where every SKU lives cuts down on time spent hunting through bins or racks.

- Audit warehouse layout quarterly. Growth often outpaces floor planning. Reconfigure when needed—not just when it becomes a problem.

Inventory accuracy doesn’t happen in spreadsheets—it happens in your warehouse. And efficiency on the floor is one of the clearest paths to better margins.

What's the Impact of These Inventory Management Challenges?

Every inventory mistake has a cost—and often, it hits more than one part of your business. Below is a breakdown of how these challenges show up across operations, finances, and customer experience.

| Challenge | Operational impact | Business consequence |

|---|---|---|

| Overstocking / Understocking | Mismatched stock levels, delayed fulfillment | Tied-up cash, increased holding costs, lost revenue from stockouts |

| Forecasting inaccuracies | Unreliable demand planning, late reorders | Missed sales, excess inventory, margin erosion |

| Lack of real-time tracking | Order delays, mispicks, manual reconciliation | Higher fulfillment costs, lost trust with customers |

| Poor inventory visibility | Conflicting stock counts across channels | Overselling, fulfillment errors, customer complaints |

| Supply chain disruptions | Lead time volatility, late shipments | Stockouts, delayed launches, churn during high demand |

| Inventory loss / Obsolescence | Spoilage, damaged goods, expired or outdated SKUs | Write-offs, wasted storage space, reduced profitability |

| SKU proliferation | Complex picking, slower counts, low-performing SKUs | Operational drag, wasted labor, inflated storage costs |

| High carrying costs | Inefficient warehouse space and stock turnover | Lower margins, cash flow pressure |

| Seasonal demand spikes | Overstock pre-season, stockouts during peak | Missed promo windows, excessive markdowns post-season |

| Compliance failures | Incorrect labeling, missing documentation | Fines, product holds, reputational risk |

| Manual documentation | Entry errors, delayed updates | Poor data reliability, reactive decision-making |

| Warehouse inefficiencies | Slow receiving, disorganized inventory locations | Bottlenecks, higher labor costs, delayed shipping |

TL;DR: These aren’t just technical hiccups.

Inventory challenges drag down every part of your business—from profitability to customer satisfaction. And the longer they go unchecked, the more expensive they get to fix. Having a comprehensive inventory management requirements checklist can help prevent these costly mistakes.

The Best Inventory Management Tools for Avoiding Pitfalls

You’ve seen the challenges. The next step? Use the right tools to fix them—before they compound into bigger problems.

Whether you’re running a growing ecommerce brand, a multi-channel operation, or a full-scale enterprise, the right inventory management software will give you key features like:

- Real-time visibility across channels

- Smarter demand forecasting

- Automated replenishment and reorder points

- Fewer errors, faster fulfillment, and cleaner data

Below are curated software roundups based on your business size and complexity—each one reviewed by industry pros and updated for today’s inventory demands.

General inventory management software

Best for: Small to midsize businesses looking for flexible, user-friendly inventory systems.

If you’re moving off spreadsheets or looking to streamline your workflows, start here. These tools offer solid tracking, reordering, and multi-location support—without the enterprise price tag.

Enterprise inventory management systems

Best for: Large ecommerce operations or omnichannel retailers managing complex supply chains.

These systems integrate tightly with ERPs, WMS platforms, and 3PLs—supporting advanced forecasting, compliance, SKU-level reporting, and supplier coordination. For a comprehensive comparison of the best omnichannel inventory management solutions, explore our detailed rankings and reviews.

Ecommerce inventory management software

Best for: DTC brands, marketplaces, and online retailers who need real-time syncing across sales channels.

These tools specialize in integrations with Shopify, Amazon, WooCommerce, and other platforms—plus order tracking, dynamic stock levels, and fulfillment optimization.

From aviation to auto shops, parts inventory software keeps critical stock exactly where it should be. And if you want something for the little guys, our roundup of the best IMS for small businesses is just the ticket.

Stop Letting Inventory Run the Show

Let’s be honest: most inventory problems don’t start in the warehouse—they start with broken systems, outdated processes, and wishful thinking masquerading as forecasting.

The good news is that every challenge we’ve covered—stockouts, shrinkage, tracking gaps, warehouse chaos—is fixable. With the right strategy and a system that can actually keep up, inventory can shift from cost center to competitive edge.

You don’t need perfection.But you do need visibility, consistency, and software that's smarter than your spreadsheet.

So pick your battles. Automate the busywork. Tighten the workflows. And invest in a setup that helps you grow without the inventory surprises.

Because at the end of the day, inventory isn’t just what you sell—it’s how well you run your business.

Retail never stands still—and neither should you. Subscribe to our newsletter for the latest insights, strategies, and career resources from top retail leaders shaping the industry.