Reorder points act as a critical inventory alert, signaling when it’s time to restock. Maintaining the right balance ensures you avoid stockouts or excessive inventory, keeping operations smooth.

Regularly updating your reorder points prevents those unwelcome stockout surprises, ensuring you always have enough stock to meet customer demand without delays.

Properly managed reorder points help prevent unnecessary excess inventory, which can lead to increased storage costs and tied-up capital better used elsewhere.

Achieving the right reorder point means hitting the sweet spot of having just enough inventory—avoiding the extremes of too much or too little stock.

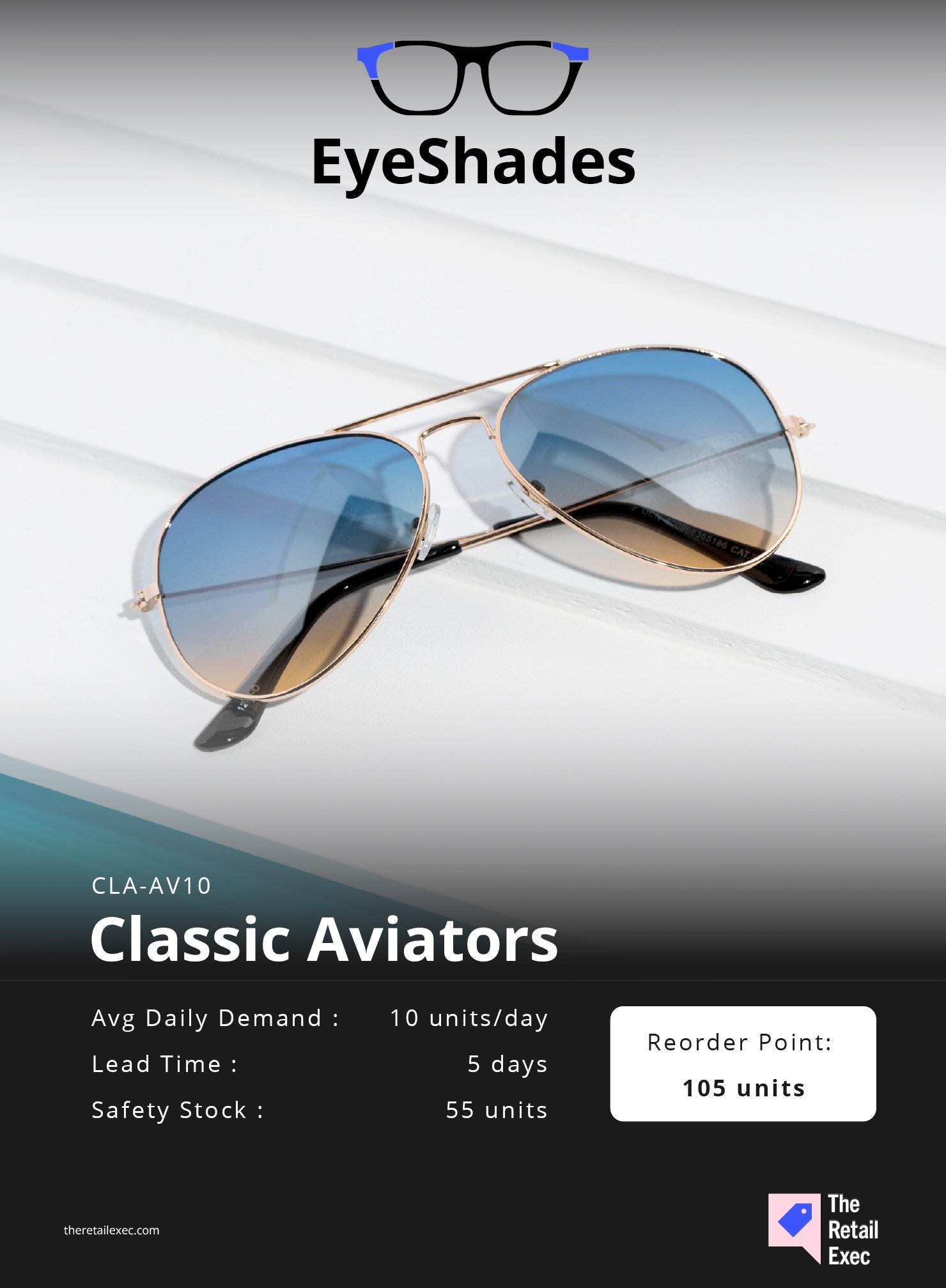

Learn from EyeShades, a fictional sunglasses brand, about the critical role reorder points play in efficiently managing their bestseller, the Classic Aviator line.

When’s the last time you updated your reorder points?

Did my question give you pause?

If it did, you’re most likely overdue and chances are, the consequences are already showing up in your inventory performance like a sore thumb.

Let’s go over the importance of reorder points, and why this seemingly small detail can make the difference between painful stockouts, costly excess inventory, and that ideal “Goldilocks” zone where the balance is just right.

What is a Reorder Point (ROP)?

A reorder point (ROP) represents the inventory level beyond which you’ll run out of stuff to sell. Consider it your built-in indicator for replenishment.

The right number allows you to continue doing business while waiting for the new orders to arrive, without overloading your warehouse with excess inventory.

Let's take a look at a fictional sunglasses brand named EyeShades and how they restock their bestselling line, the Classic Aviator.

They’ve figured out that when their inventory for Classic Aviators drops to a certain level—say, 105 pairs—they need to reorder immediately.

How did EyeShades come up with this figure? Not by guesswork. There’s a science to calculating reorder points.

I’ll walk you through exactly how to arrive at that number, step by step. But first, let’s talk about the relevance of setting up the right reorder points.

Why Reorder Points Matter in Retail

ROPs help maintain product availability without overstocking. What does this mean for your business, particularly in terms of inventory management?

- Fewer lost sales. More than 50% of shoppers couldn’t get their hands on a product they wanted to buy due to it being sold out. Since you’ll be replenishing your products in a timely manner, you’ll be able to capture sales that might otherwise be lost.

- Happier customers. Salesforce reported that 64% of customers prefer companies that can cater to their needs in real-time. Even if your products are excellent, customers won’t wait around forever. They’ll get frustrated and find someone else.

- Lower holding costs. Carrying costs generally make up between 25% and 30% of total inventory value. If you order too soon or too often, you’ll inflate these expenses.

- Better supply chain efficiency. Accurate reorder points prevent last-minute scrambles and inconsistent supplier scheduling.

After learning why sharpening your reorder points offers substantial inventory management benefits, let's look at how to calculate them.

How to Calculate Reorder Points Step by Step

Reorder points can be calculated through the time-tested ROP formula:

ROP = (Average Daily Usage × Lead Time in Days) + Safety Stock

If this sounds like gobbledygook to you, hang tight.

I’ll break down each component below with the help of our fictional sunglass brand, EyeShades.

1. Figure out your average daily usage

Your daily usage refers to the number of units you typically sell per day. You can also refer to it as “average daily sales” or “demand rate”.

Here’s the formula:

Average Daily Usage = Total Units Sold / Number of Days

Let’s say EyeShades sold 300 pairs of Classic Aviators over the past 30 days. Using the formula we get:

300 / 30 = 10 units per day

Therefore, their average daily usage = 10 pairs of Classic Aviators per day.

2. Measure your supplier lead time

Lead time is the number of days it takes to receive new stock after placing an order.

Several factors influence it, including supplier reliability, shipping methods, and customs clearance if you're ordering internationally.

Let’s say EyeShades typically receives inventory from their supplier in Italy within 5 days.

Lead time = 5 days

They came up with this number after looking through historical lead time averages.

3. Calculate lead time demand

Now, you need to know how much inventory you’ll go through over the course of that lead time.

It’s called your lead time demand, and this is how you calculate it:

Lead Time Demand = Average Daily Usage × Lead Time

We’ve already established the following numbers for EyeShades:

- Average daily usage = 10 units/day

- Lead time = 5 days

So, using the formula:

10 × 5 = 50 unitsThis means EyeShades should have at least 50 pairs of Classic Aviators on hand to meet demand while the next batch crosses international waters.

4. Add in your safety stock

The purpose of safety stock is to provide a buffer against unexpected spikes in demand or delays in the supply chain.

It differs from cycle stock, which is just your regular daily inventory.

You need to figure out the amount that puts you into the sweet spot where you don’t run out but also don’t end up with excess stock. As ever, the magic of math saves the day.

Here’s a simple safety stock formula:

Safety Stock = (Max Daily Usage × Max Lead Time) − (Average Daily Usage × Average Lead Time)

Let’s say that:

- On a really busy day (such as a summer promotion), EyeShades might sell 15 units

- The longest supplier delay EyeShades has faced is 7 days

Then:

(15 × 7) − (10 × 5) = 105 − 50 = 55 units

So, EyeShades needs 55 units as a cushion if something goes sideways.

5. Put it all together in your reorder point calculation

Now, let’s bring all the components together with the formula at the beginning of this section.

Here’s a refresher:

ROP = (Average Daily Usage × Lead Time in Days) + Safety Stock

Using our numbers, we’ll get:

ROP = (10 × 5) + 55

ROP = 50 + 55 = 105 units

EyeShades need to reorder their Classic Aviators when inventory drops to 105 pairs.

It gives the business just enough inventory to cover the next few days of regular sales-plus a buffer in case of the unexpected.

Want to skip the math?

Use an Excel Sheet. Or better yet, try our Reorder Point Calculator Tool to plug in your own numbers and get results in seconds:

4 Advanced ROP Techniques to Master Your Replenishment Strategy

The basic formula gives you some protection, but it can easily go over or under depending on real world conditions your business faces.

Advanced ROP techniques help come up with a number that tunes into your specific business needs.

To illustrate, we’ll see if 105 really is the optimal ROP for EyeShades’ Classic Aviators.

The eyewear company never lacks products, and sales numbers are always good. But they realized their inventory holding costs could be better.

They want to go leaner, so they implemented the following tips:

1. Apply service level targets

Have you heard of the term “the supply chain triangle”?

It refers to the delicate balance between cost, cash, and service in supply chain management—and managing it well is often seen as the ultimate challenge.

So where does reorder point optimization fit into this triangle? It plays a big role in the “service” corner.

Your service level reflects how much protection you want against stockouts or backorders.

At first glance, setting a 100% service level seems like the obvious answer.

Hold your horses, though: Higher service levels mean fewer chances of running out of stock, but they also drive up your carrying costs.

Choosing targets like 90%, 95%, and 99% service levels are more suitable, depending on the balance between customer satisfaction and inventory cost you want to strike.

- A 90% service level means you’re willing to risk stockouts 10% of the time. It keeps inventory lean, but you’ll have to accept that lost sales can be in the cards for you.

- A 99% service level is common for critical items where stock outs would be very costly. It means you’re ok to absorb the carrying costs to make sure you never run out.

Audit your current service levels by product and across your inventory as a whole. If they’re already in a good place, simply tweak depending on your current situation.

You also need to differentiate SKUs by volatility because ROPs don't work the same way for all your goods.

Group products based on demand stability and assign service levels accordingly.

For example, EyeShades’ Classic Aviators, a consistent top-seller with a steady market, might qualify for a 95% service level. It’s high enough to meet demand, and since the product flow is predictable, EyeShades is willing to take a 5% risk.

Meanwhile, a less popular model like the Retro Round Frames, which regularly faces fluctuations, could require a 99% service level to cope with sudden demand spikes and long supplier lead times.

2. Use standard deviation to fine-tune safety stock level

I know, I know.

You already know how to compute safety stock, but the equation I gave you above isn’t cut out to handle real-world variability.

Sales fluctuate day to day, and lead times can be anything but consistent. Relying only on the averages and maximums can’t yield the accuracy your business deserves.

That’s where a more advanced formula comes in—one that factors in standard deviation, a measure that captures the uncertainty in both lead time and demand.

It looks like this:

Safety Stock = Z × √[(Average Lead Time × (Demand Standard Deviation)²) + (Average Demand)² × (Lead Time Standard Deviation)²]

Here’s the breakdown:

- Z - A Z-score connects your service level to a real number you can use when calculating reorder point calculations.

- Average lead time: The time period (usually in days) between placing an order and receiving it.

- Demand standard deviation: A measure of how much the daily demand differs from the average.

- Average demand: Your daily average sales volume.

- Lead time standard deviation: The variation in your supplier’s delivery times.

Let’s say EyeShades is now using this advanced method to fine-tune the amount of inventory for their Classic Aviators.

Here’s what they know:

- Average daily demand = 10 units

- Demand standard deviation = 3 units

- Average lead time = 5 days

- Lead time standard deviation = 2 days

- Desired service level = 95% → Z = 1.65

Plugging into the formula to complete the safety stock calculation, they get:

Safety Stock = Z × √[(Lead Time × Demand SD²) + (Demand² × Lead Time SD²)]

445 → √445 ≈ 21.1

1.65 × 21.1 ≈ 34.8

Advanced safety stock = 35 units

With the basic formula, we ended up with 55 units after using the maximum lead time and usage. The advanced method reduces it to 35, based on actual variability and your desired service level.

This lowers the reorder level to 85 units.

ROP = (daily usage × lead time) + safety stock

ROP = (10 × 5) + 35 = 85 units

EyeShades should reorder when stock hits 85 units to cope with normal demand and unexpected bumps. If they forego standard deviation, they’ll end up with more products on their shelves than they need (hint: 105 units).

3. Factor in seasonality and trends

The basic reorder point formula doesn’t account for the peaks and troughs caused by seasonality and trends.

This is a recipe for stock outs during high-demand seasons or cash shortages during slow seasons.

For example, EyeShades sees a huge spike in demand for their Classic Aviators during the summer months when everyone’s heading to the beach, and again around the winter holidays when shoppers are hunting for gifts.

If EyeShades used the same ROP year-round, they wouldn't be able to process orders during these busy periods.

Therefore, they tweak ROPs ahead of known demand spikes, like peak sales, promotions, and new releases, using real-time, hard data. Not guessing based on memory.

They understand that old assumptions don’t factor in evolving customer and market changes.

Follow their lead by looking at:

- Your historical sales data

- Demand forecasting and sales projections

- Customer buying trends

- Supplier timelines around busy seasons

Data-backed decisions will help you raise your reorder points proactively and scale back as soon as the demand drops.

4. Use dynamic ROPs with real-time data

ROPs aren’t meant to be static—yet so many businesses set them once and forget about them.

Over time, this neglect creates large gaps between what your inventory needs today and when you first set those numbers.

Linnworks recommends updating your reorder points quarterly and anytime you experience major changes, like new product launches, supplier shifts, or market expansions.

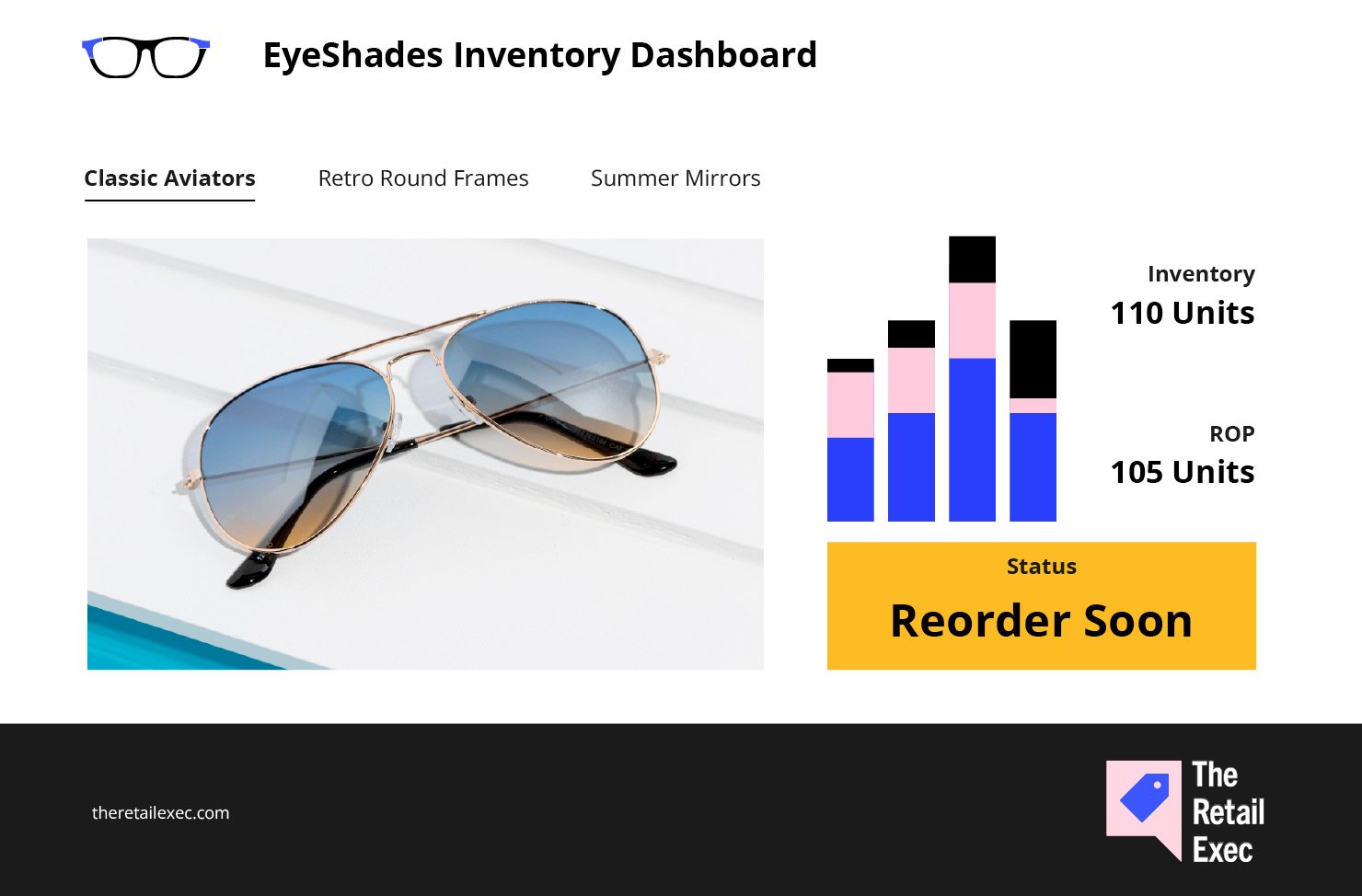

Let’s say, EyeShade’s lead time for the Classic Aviators jumps from 5 to 9 days.

If their ROP stays the same, they’re only setting themselves up for stockouts. If sales take off and they don't make timely tweaks, they will be in the same boat.

Keeping ROPs dynamic means continuously syncing them to what's happening in real time, rather than what was true a year back.

Now, all these advanced tips are important.

But let's be real: Updating reorder points manually for hundreds or thousands of SKUs, while tracking all the moving variables like sales trends, supplier reliability, and seasonality, is exhausting and error-prone.

That’s why smart businesses lean on sophisticated systems to do the brunt of the work and improve inventory management overall.

Top Software to Streamline Your ROP Calculations

Inventory management platforms keep all the relevant, accurate data in one spot by tracking your inventory through your multiple distribution channels.

These perpetual systems give you a real-time view of your sales performance and inventory turnover, so you can determine the best order points. Or better yet, let your tool's algorithms calculate them for you.

Your IMS also adapts as needed.

If a product's demand increases or the vendor's lead time changes, the system will recalculate the safety stock and ROPs to account for these variations.

Last but not least, this type of software can alert you when your stock levels are approaching reorder points, so you can monitor replenishment (which by the way, it can also automate!).

Choose an IMS that possesses these features to optimize your reorder points, and in turn, give you better inventory control.

Here’s a list of reliable inventory management systems to consider:

Use Strong ROP to Pull Your Brand Up

Having a smart ROP strategy is your step toward fewer stockouts, fewer wastes, and better retail performance.

But don’t think you need to bear the burden of all this work on your (or your team’s) shoulders.

The right inventory management software can take it off of you. Aside from the list above, here are two more tool roundups that can help you find the right pick.

- The 18 Best Free Inventory Management Software for SMBs, Reviewed & Compared for 2025

- The 20 Best Enterprise Inventory Management Software, Reviewed & Compared for 2025

Check out these other related topics as well:

- ABC Inventory Analysis Explained + Strategies to Improve Efficiency

- How to Manage Perishable Inventory: 8 Strategies, Challenges, & Top Tools

Retail never stands still—and neither should you. Subscribe to our newsletter for the latest insights, strategies, and career resources from top retail leaders shaping the industry.

Reorder Point FAQs

You might still have some questions. Lucky for you, the experts have the answers:

Can I use the same reorder point for multiple locations or warehouses?

It might not be as effective. Every business site has unique requirements.

Riley Westbrook, co-founder of Valor Coffee, shares his experience to explain why:

“The flagship café needs restocking at a higher frequency compared to the roastery because its focus is on providing bulk orders for wholesale.

Our business locations would experience stock imbalances if we applied the same reorder point system to multiple sites.

The diverse levels of traffic and sales numbers and supply chain speed between each site warrant individualized reorder points for effective resource management across all locations.”

He advises setting ROPs per individual location to ensure that each one receives the precise amount of required inventory without excess stock or supply shortages.

What’s the difference between reorder point and reorder quantity?

The reorder point refers to the level of inventory that signals it’s time for replenishment. Meanwhile, Dani Mechlowitz, managing Director at Delta Fulfilment, describes the reorder quantity (ROQ) as “how much to order when you hit that trigger point.”

Is there a difference between ROP for finished goods vs. raw materials?

Yes. Brian Lim of I Heart Raves underlines the major difference: “For finished goods, ROP usually considers customer demand and lead time, while for raw materials, ROP will likely have to consider production schedules as well as the supplier’s reliability.”

Can reorder points work with subscription or recurring product models?

Yes, of course. It just takes a change in your reorder point computation to account for subscription commitment. You can even lower safety stock because you have a clearer picture of what future demand looks like. But basically, the formula remains the same.