Stock Wastage: Over $163 billion worth of goods expire annually in the US, highlighting the need for efficient stock rotation.

Rotation Failures: Stock rotation often fails due to hidden expiry dates, poor layouts, and incentivized speed over accuracy.

Rotation Strategies: FEFO, FIFO, and LIFO should be strategically matched to SKU profiles to reduce wastage and improve turnover.

Automation Tools: Barcode scanning, WMS, and IoT sensors enhance visibility and efficiency in stock rotation processes.

Performance Metrics: Key KPIs like inventory turnover and spoilage rate prove the financial impact of effective rotation strategies.

The stakes are high—and perishable.

Every year, over $163 billion worth of expired or unsellable goods gets tossed in the US alone. And despite having FIFO on paper, a lot of warehouses still end up with yogurt six weeks past its sell-by sitting quietly behind a pallet of fresh stock.

Spoilage, stranded inventory, and floor-level errors aren’t just operational annoyances—they’re profit leaks. And they’re avoidable.

If you’ve ever had a team member shrug and say, “We rotate stock like we’re supposed to,” right before a manager finds an entire layer of expired product, this guide is for you.

We’re going to get into:

- When to ditch FIFO for FEFO (and why LIFO is mostly a tax-side myth)

- The flow layout designs that make “doing it right” physically easier

- Barcode and WMS tactics that keep expiry dates front and center

- And the KPIs that actually move finance to say yes to tech and process upgrades

Let’s turn rotation into a competitive moat—not a compliance box.

Why Stock Rotation Still Fails

Waste persists because teams can’t see product age, can’t easily reach the right unit, and often don’t trust the process enough to follow it.

Globally, 8% of all inventory ends up as waste—and in the US alone, that’s a staggering $163.1 billion in write-offs and trash fees every year. Most rotation programs don’t fail because people don’t care. They fail because:

- Teams can’t see which pallet or carton is oldest. Lot codes are buried, expiry dates aren’t scanned at receiving, and systems don’t surface risk until it’s too late.

- The floor layout works against the rules. A newer pallet gets dropped in front of an older one. Rearranging heavy inventory just to reach “the right one” becomes a low-priority task.

- The metrics don’t back up the culture. If pick speed is rewarded but pick accuracy to FEFO/FIFO is not, speed wins.

Rotation policies sound good in SOPs. But unless your warehouse makes the right move also the easy move, it’ll get skipped in the crunch.

FIFO, FEFO, LIFO—Choose Your Weapon

Not all SKUs should follow the same rules. FEFO is essential for perishable goods, FIFO works for slow-aging items, and LIFO is usually a financial concept—not an ops reality.

Let’s keep the definitions clean:

- FIFO (First In, First Out): Oldest stock is picked first.

- FEFO (First Expired, First Out): Earliest expiry date wins, even if it arrived later.

- LIFO (Last In, First Out): Newest stock goes out first—used in accounting, but not viable in most physical flows.

So how do you decide? You match the method to the core risk:

- FEFO for products with safety or quality risk if expired (dairy, pharma, cosmetics)

- FIFO for items with slow decay or obsolescence risk (apparel, electronics)

- LIFO almost never used operationally—IFRS doesn’t allow it for financial valuation

Here’s a quick table to keep it straight:

| Method | Ideal products | Core risk | Tech requirements |

|---|---|---|---|

| FIFO | Shelf-stable goods, slow-moving SKUs | Obsolescence, hidden age | Location discipline, gravity flow racks |

| FEFO | Perishables, temperature-sensitive SKUs | Safety, quality, compliance | Expiry capture (GS1 AI-17), lot tracking, WMS rules |

| LIFO | Rare use; bulk commodities | Low—mostly theoretical | None (not supported by most systems) |

You can also combine methods by SKU family.

At Mesa Trail Outfitters—our fictional outdoor gear and nutrition brand—they run FEFO for their seasonal protein bars and supplements, FIFO for rental gear and apparel, and fixed-location rules for long-shelf-life accessories.

The trick is keeping method logic clear in your WMS and labeling.

Matching Methods To SKU Profiles & Risk

Segment your inventory by shelf life, demand volatility, and unit value—then apply the simplest method that protects your margin and tightens inventory control.

The right stock rotation method isn’t universal—it’s strategic.

A protein bar with a 6-month shelf life, a $2 cost, and high seasonal velocity shouldn’t follow the same logic as a $400 rental tent that depreciates slowly over years. That’s why smart stock management starts with segmentation.

Start by segmenting SKUs into four dimensions:

- Shelf life. Is there a known expiration or performance decay timeline?

- Demand volatility. How predictable is the movement of this SKU?

- Unit value. What’s the dollar impact of spoilage or obsolescence?

- Regulatory exposure. Are there safety, labeling, or compliance rules?

Then assign methods accordingly:

- Short-life, high-risk SKUs → FEFO

- Mid-life, medium-risk SKUs → FIFO

- Long-life, low-risk bulk → FIFO or fixed-location logic

- Serialized assets → service-based rotation or warranty alignment

At Mesa Trail Outfitters, they apply FEFO to their seasonal nutrition packs—especially those that degrade with summer heat in southern markets.

Their rental tents and gear follow FIFO, while low-cost items like carabiners sit in bin locations that get re-counted weekly rather than rotated.

This rotation logic not only reduces spoilage—it improves inventory turnover and supports healthier replenishment cycles across the board.

Color-coding bins or shelf tags based on rotation risk tier (e.g., red = FEFO, yellow = FIFO, green = non-rotated) is a simple but powerful nudge.

It makes the expected method instantly visible to every picker, even when they’re moving fast.

Automating Rotation: WMS, Barcodes & IoT Sensors

You can’t enforce what your system doesn’t know. Automation keeps expiry and risk visible—without slowing down the floor.

Modern inventory management software makes this visibility automatic and scalable.

The biggest win for rotation programs? Getting the system to do the remembering.

Here’s what that looks like, tier by tier:

- Basic WMS: Supports FIFO logic by location; rules for putaway and pick order.

- Advanced WMS: Supports FEFO via lot tracking and expiry-aware pick directives—especially useful for any inventory tracking system built for perishables.

- Voice-enabled picking: Adds real-time prompts (“pick lot 2304-01, expires June 3”).

- Barcode scanning: GS1 standards (especially AI-17 for expiry) enable machines to catch what humans miss—critical for any modern warehouse barcode system.

- IoT sensors: Temp sensors, BLE beacons, and RFID tags automate condition monitoring and reduce surprise spoilage.

Manual entry error rates hover around 1 in 300 keystrokes. With barcode scanning, that drops to 1 in 10,000—or better with 2D barcodes.

The difference between a good barcode and none at all is thousands of dollars in avoidable waste.

GS1’s AI-17 field standard for expiry dates (used in GS1-128 and GS1 DataMatrix formats) makes FEFO automation possible—and it’s increasingly required in healthcare and CPG.

It’s not just about compliance. Those same labels can help your system alert when pickers bypass older stock or when inventory replenishment thresholds are at risk.

Tools with real-time alerts—like top inventory replenishment software—help flag slow turns before they become spoilage.

At Mesa Trail, they added 2D barcode scanning to their nutrition SKUs and linked it to voice pick prompts through their WMS. Within one season, they saw a 32% drop in write-offs and a measurable uptick in inventory turnover. The tech paid for itself in under five months.

But rotation success doesn’t come from one system—it takes the right mix of software to decide, direct, and enforce stock movement.

To make smarter decisions about what to rotate—and when—you’ll need inventory software built for optimizing shelf life, demand, and replenishment:

To actually enforce FIFO or FEFO on the warehouse floor, your WMS needs to know expiry dates, lot numbers, and pick logic:

We’ll break down the ROI math in the next section.

Designing A Warehouse Flow That Enforces FIFO/FEFO

Layout is half the battle. The right floor plan makes the right product easier to reach—and harder to mess up.

Start with the golden rule: stock should flow in one direction. This is the foundation of warehouse layout optimization.

A U-shaped layout (inbound receiving and outbound shipping on the same wall) minimizes transit distance and helps isolate pick zones. Add one-way aisles with forward-pick faces stocked from the back.

This creates a literal flow of first-in → first-out product movement.

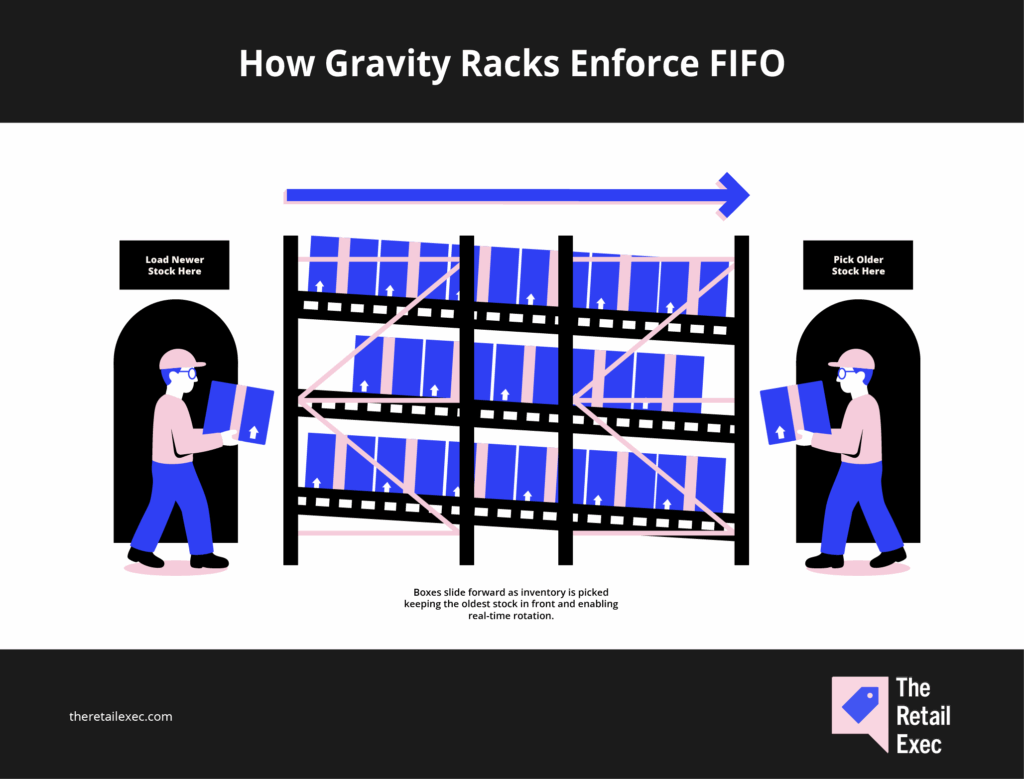

Gravity racks, also known as carton flow systems, are shelving units designed to enforce FIFO automatically. Inventory is loaded from the back and moves forward on sloped rollers or tracks.

As workers pick from the front, the next case slides into position—no need to reshuffle or guess which pallet is older.

No need to reshuffle pallets—or rely on memory.

At Mesa Trail, they converted their nutrition zone to use gravity racks with rear loading and front-pick faces. That single change helped boost FIFO compliance with even their newest floor staff.

Even with seasonal surge hires, stock management efficiency and rotation compliance jumped.

What's that look like, you say? Here's the general system in action:

KPIs & Dashboards: Proving ROI To Finance

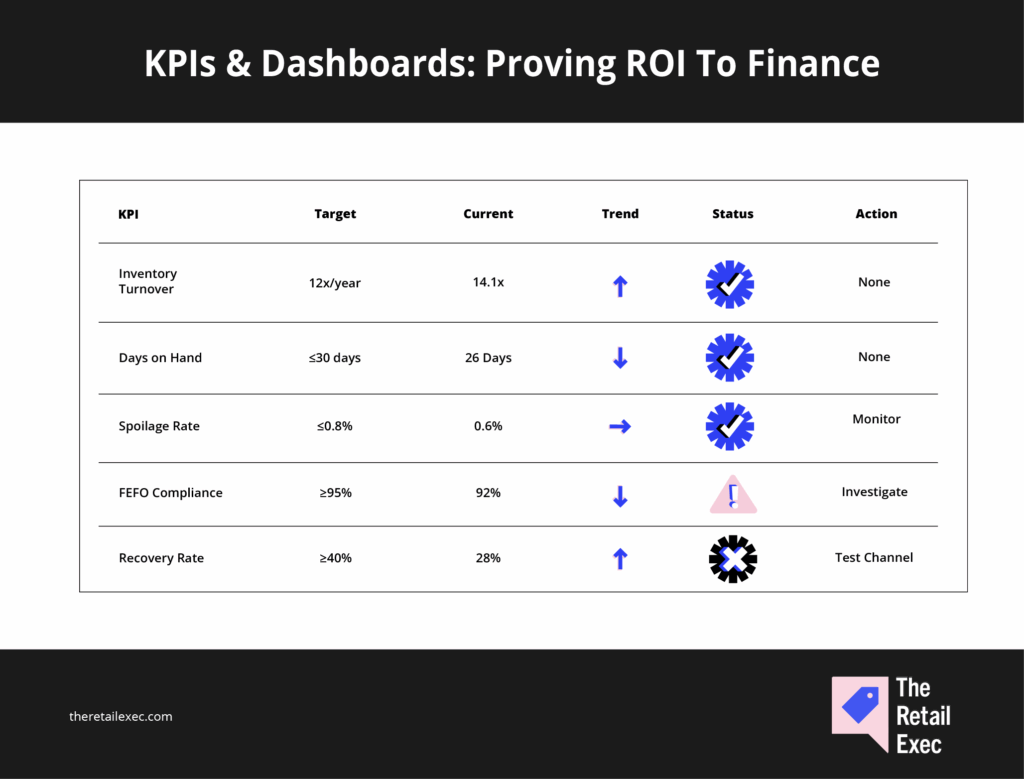

Finance needs to see what rotation changes actually deliver. These five KPIs show impact on waste, cash flow, and efficiency:

| KPI | Target | Current | Trend | Status | Action |

|---|---|---|---|---|---|

| Inventory turnover | 12x/year | 14.1x | ↑ | ✅ | None |

| Days on hand | ≤30 days | 26 days | ↓ | ✅ | None |

| Spoilage rate | ≤0.8% | 0.6% | → | ✅ | Monitor |

| FEFO compliance | ≥95% | 92% | ↓ | ⚠️ | Investigate |

| Recovery rate | ≥40% | 28% | ↑ | ❌ | Test channel |

An effective stock rotation strategy only gets traction when leadership sees the bottom-line impact.

Here are the five KPIs Mesa Trail Outfitters used to get finance—and frontline teams—fully on board:

- Inventory turnover = Cost of Goods Sold ÷ Average Inventory

- A core efficiency metric. Mesa track this weekly for perishable goods, monthly for higher-value gear.

- Days on hand (DOH) = 365 ÷ Turnover.

- For short shelf life SKUs, they set maximum thresholds to trigger markdowns or reallocation.

- Spoilage rate = Spoiled inventory ÷ Received inventory.

- Tracked by category to spot where FEFO rules or FIFO stock rotation needs improvement.

- FEFO compliance = % of picks made from the earliest-expiry lot.

- Their inventory management system alerts us when compliance drops below 95%.

- Recovery rate = Revenue from discounted/resold stock ÷ Cost of that stock.

- Shows how well they salvage older stock when it’s at risk of becoming deadstock.

To actually track and improve these metrics, you need real-time dashboards that integrate your WMS, replenishment triggers, and expiration dates.

Need the tooling to support these KPIs long-term? Check out our guide to inventory management software features that make metrics actionable.

What To Do When Stock Gets “Stuck”

When aging inventory won’t move, act fast: move it, mark it down, or escalate. Even with smart forecasting and expiry tracking, some SKUs get stuck.

At Mesa Trail, they tag anything 30% past expected shelf life or approaching its use by date as a candidate for intervention.

Use this 3-step framework to streamline your response:

- Move. Relocate to a higher-velocity zone or push via ecommerce channels.

- Mark down. Use a pricing ladder or bundle with newer stock to preserve perceived product quality.

- Mayday. Route to secondary markets, donation partners, or disposal—ideally before food safety risks or compliance issues arise.

The key is to act before spoilage becomes a loss. Mesa uses a flowchart to help team leads make fast, repeatable decisions.

Industry-wide, recovery from out-of-date liquidation channels often lands under 10%. That’s why fast action beats salvage.

Quick-Start Checklist & 90-Day Rollout Plan

Start small, automate where it counts, and scale by aisle—not by facility.

Here’s how Mesa Trail phased in their stock rotation overhaul without disrupting supply chain flow:

- Week 1: Audit SKUs, shelf life, and lot tracking status. Flag any perishable products lacking clear expiry visibility.

- Week 2: Assign methods (FIFO, FEFO, LIFO where needed) by product type. Document rotation logic.

- Week 3: Define barcode standards (GS1 AI-17 for expiration dates). Order compliant label stock.

- Week 4: Configure your inventory management system to automate FIFO and first expired rules.

- Week 5: Launch a pilot in one zone (e.g., nutrition aisle). Observe how staff handle older products versus newer products.

- Week 6: Add voice-pick prompts and barcode scanning to reduce human error.

- Week 7: Install carton flow racks or redesign layout to reduce blocked access to older items.

- Week 8–9: Launch dashboards with real-time inventory levels and spoilage alerts.

- Week 10–11: Expand to adjacent aisles. Share usage and restocking data with suppliers to optimize rotation upstream.

- Week 12: Review performance with finance. Finalize incentives and metrics to reinforce rotation discipline.

To keep their ops team aligned, Mesa built a Trello board that mirrors this rollout.

Need help selecting tools that make rotating stock and expiry control automatic? Our guide to inventory replenishment software covers tools that streamline stock levels, reduce overstocking, and protect customer satisfaction.

Turn Rotation Into a Competitive Moat

A good stock rotation program builds margin, improves trust with suppliers, and protects product quality. It also keeps your perishable items from stinking up the place, which is quite nice.

If age is visible, the path is clear, and metrics drive behavior, you’re not just maintaining effective inventory management—you’re building a real advantage.

Mesa Trail went from shrugging at shrink to using expiry as a performance lever.

That’s what the importance of stock rotation looks like in action.

Retail never stands still—and neither should you. Subscribe to our newsletter for the latest insights, strategies, and career resources from top retail leaders shaping the industry.

Stock Rotation FAQs

We’re at the end, but maybe you were asking yourself these questions and finding no answer? We’ve got ya covered.

Does stock rotation apply to non-perishable items?

Yes—products without a formal expiration date can still go out-of-date due to obsolescence, damage, or style changes. Rotating stock helps avoid deadstock and protects working capital.

How do I implement stock rotation in a small warehouse?

Start with FIFO using physical cues like labeling and one-way aisles. Track expiry dates manually or in a basic inventory management system, then scale to automation when your volume grows.

What’s the difference between expiry, use by, and best before dates?

Expiry dates indicate safety limits. Use by dates reflect peak freshness. Best before is about quality, not safety. For perishable products, FEFO should prioritize expiry or use-by dates.

Can I mix FIFO and FEFO in one stockroom?

Absolutely. Many retailers and warehouses use FEFO for temperature-sensitive goods and FIFO for everything else. Just ensure your pick paths and WMS rules align with each method.

What causes rotation strategies to fail?

Human error, blocked access to older products, poor labeling, and lack of system alerts. An effective rotation strategy addresses layout, labeling, tech, and training—not just policy.