Oops, Did It Again: Constant mistakes can lead to embarrassing apologies and damage customer trust. Ensuring smooth operations helps avoid sour experiences for both businesses and customers.

Google Reviews Gone Wild: Mistakes not only lead to costly returns but can also result in negative online reviews, affecting a business’s reputation and potentially deterring future customers.

The Return Cost Blues: Errors increase the likelihood of expensive returns, hitting the bottom line. Reducing fumbles can save money and improve overall customer satisfaction.

Embarrassment on Repeat: Consistently poor performance can result in red-faced embarrassment, harming a business's image and pushing customers away.

Avoid the Sour Orange: Ensuring operational excellence can prevent the repetitive taste of sour consequences, creating sweeter interactions with customers and preserving business reputation.

Imagine biting into a sour orange. Again and again. And again.

That's the taste of the red-faced embarrassment every time your behind-the-scenes fumbles result in customer-facing apologies, expensive returns, and potentially scathing Google reviews.

These (financially) draining faux pas quite literally begin and end with leaky order management:

- Wait, didn't we sell out these kaftans already? Why are they still live on the website?

- How is it possible for delivery to take so long when Amy's order was shipped a week ago?!

- Didn't we order packing materials last month? We're already out?

Fret not. I've done my work—talked to veteran ecommerce business owners and collected a toolkit of strategies, so you can do yours—sell, ship, and succeed.

What is Order Management?

Order management manages the entire customer order lifecycle.

The process starts when an order is placed, continues through tracking and processing, and ends when the package is delivered to the customer.

In order management for ecommerce, there are additional tasks like routing orders to the appropriate warehouses, printing shipping labels, handling returns, and managing subscription services.

The ecommerce order management system synchronizes each step from the moment a customer clicks “buy” until the package arrives at their doorstep.

B2C order management is one thing—B2B is a whole different beast, with bulk orders, longer sales cycles, and way more moving parts. Master the complexity with our B2B order management guide.

Order management vs order fulfillment: What’s the difference?

I asked Kate—part of the marketing team at Irresistible Me—a beauty company specializing in hair extensions and wigs: how would you explain the difference between the order management and the order fulfillment process to a beginner?

Think of order management as the brain behind your store’s operations—it’s all about tracking orders from the moment a customer clicks “buy” until the product reaches their doorstep.

This includes inventory updates, payment processing, and keeping your customers in the loop.

On the other hand, order fulfillment is the muscle—it’s the actual process of packing, shipping, and delivering the order.

It’s more hands-on and happens after the order management system does its part.

What’s the big deal about order management?

Good order management extends beyond keeping your warehouse organized. Here's why it matters:

- Happy customers. Accurate orders + delivered on time = happy customers. Happy customers = repeat business + positive reviews.

- Efficiency. A streamlined order management process keeps things moving. Optimized workflows, automated tasks, and smart routing get orders out the door quickly.

- Inventory control. Know exactly what you have in stock and where it's going. Good order management prevents overstocking and stockouts.

- Cost savings. Efficient order management saves you money. Reduce labor costs, optimize shipping, and prevent errors.

4 Key Stages of the Order Management Process (+ Challenges and Solutions)

Remember how I said I tapped experts for this post?

One of them is my mother, who co-ran our thrift shop on Instagram and processed, packed, and fulfilled over 100+ successful orders—all from the four walls of our home.

I asked her to describe what the stages of order management look like, the main friction points of each, and how we might solve them:

1. Pre-sale: Inventory management (“Do we actually have the thing?”)

This is all about knowing what you have in stock, where it is, and how much is left.

⚠️ Challenges: My mother's biggest “time-waster”, according to her, was selling an item through a live listing on our Instagram page, collecting the payment, logging the order, and suddenly—freezing in momentary panic.

Do we even have the thing we just sold?!

Luckily, there was only one time when we had to actually return the money to the customer saying we had miscounted our inventory. But like I said, biting into a sour orange…

✅ Solution: If you don't have real-time inventory software, you really need one. NOW.

So, here’s our list of the top 10 inventory management software for your automation needs:

(Also, choose an OMS that can handle omnichannel inventory management, providing a centralized view of your stock across all platforms—more on this soon.)

2. Order placement and confirmation (“Did they actually pay?”)

This stage is all about what happens from the moment a customer clicks “buy” to when they get that order confirmation email.

We're talking about getting customer information, sorting out payments, and making sure those order confirmation emails are sent out.

⚠️ Challenges: It can be a real headache without the right systems in place. For us, it was juggling DMs, half-updated spreadsheets, and payment notifications saved as screenshots, all the while trying not to accidentally sell the same item twice.

✅ Solution: Implement ecommerce management systems that can scale with your business growth, making sure you can handle increasing order volumes without delays.

3. Order fulfillment (packing peanuts and prayers)

This is where things get real (and potentially real messy).

Picking, packing, and shipping may sound straightforward, but there are a million small things that can seriously hurt the customer experience—and by extension, your profitability.

⚠️ Challenges: Incorrectly packaged items, misplaced orders, wrong orders sent to the wrong customers, and inefficient shipping processes that lead to delays, damaged goods, and frustrated customers.

✅ Solution: This is where you need to optimize your warehouse workflow.

Our warehouse was our living room, and we had absolutely no floor plan for optimizing our space for easier picking and packing.

Don’t make our mistake—choose your fighter below:

Invest in barcode scanners, label printers, and efficient packing stations.

And don't forget the power of a good shipping partner! Reliable carriers and optimized shipping routes can make all the difference.

4. Post-sales: Returns and follow-ups (“The return of the (slightly used) Jedi?”)

The order may be delivered, but the journey isn't quite over yet. Post-sale covers everything that happens after the purchase, including returns, exchanges, and customer support.

⚠️ Challenges: The combination of high order volume and the need for both smooth returns and great customer service creates a significant time and complexity challenge.

My mother would sometimes stay awake until 3 AM just to collect reviews, ask our customers to share photos, and make sure they knew that we weren’t “all sales and no service.”

✅ Solution: Make returns a breeze. Offer clear return policies, prepaid shipping labels, and hassle-free exchanges. Be responsive and helpful with customer inquiries, turning potential problems into opportunities to build customer loyalty.

8 Order Management Strategies for Successful Order Orchestration

Here’s how to meet—and exceed—customer expectations.

1. Invest in order management software

Let's state the most obvious solution right off the hop: there's no way you can afford to not invest in automation.

From initial customer data to final invoice and automated confirmation, integrated order management systems optimize the entire order process.

If a small business like ours, managing about only 20 orders a week, ran into trouble with manual processes, what happens when that number scales to 2,000? Or 200,000?

A logistics operation that relies on your tired body and overcrowded mind will inevitably lead to inaccurate inventory counts, poor returns management, and lowered customer satisfaction.

Basically, if you don't fix the leaky pipes on the inside, the cracks on the outside will not be far behind.

We were able to save ourselves by automating our workflows.

The implementation of automatic stock alerts resulted in a 50% reduction in the number of human updates.

Fix your leaky pipes with a solid order management solution:

2. Optimize for customer-focused order tracking

If the order's goal is to reach the customer safely, aren't all deliveries technically customer-focused? 🤔

In theory, yes. But traditional delivery operations are opaque—the order is shipped, you get a tracking link, and that’s about it, really.

However, Ben Schreiber, CMO of Latico Leather points out that “there’s a growing trend toward customer-focused order tracking, which provides more transparency and tailored updates, fostering loyalty and trust.”

Real-time updates and a clear delivery timeline turn nail-biting anticipation into “it's-on-its-way” excitement.

- Provide real-time updates. The more frequent the updates, the better. Customers love seeing their order move through the different stages. Keep them in the loop about their order status at all times.

- Offer visual tracking. A map showing the package's journey can be a fun and engaging way to keep customers informed.

- Personalize the experience. Add a personal touch with branded tracking pages or customized messages.

- Use it as a marketing opportunity. Include relevant product recommendations or promotions on the tracking page.

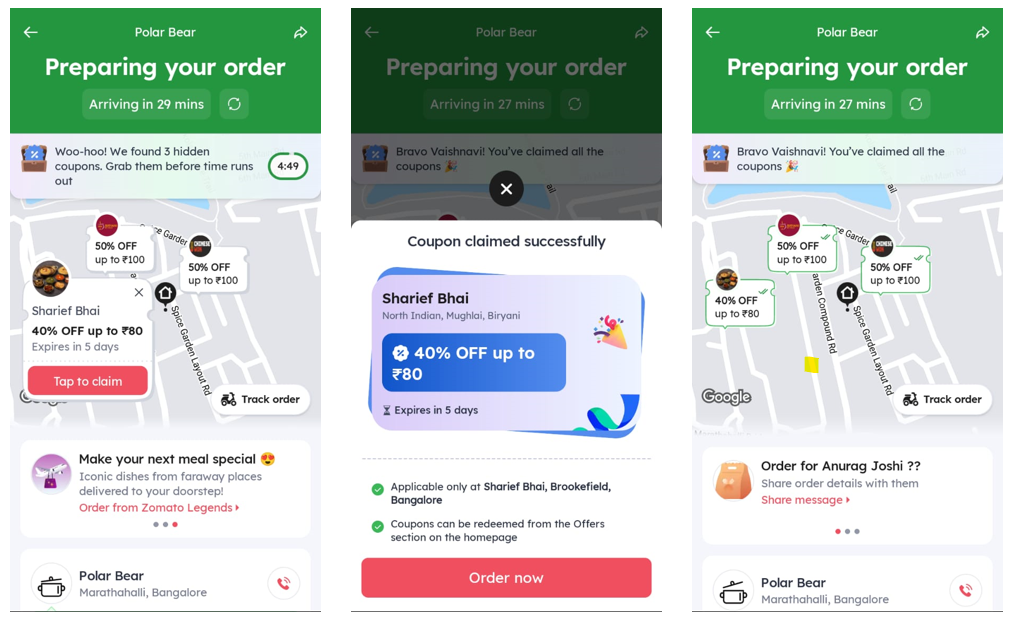

Here’s a great example of a dynamic order tracking page by the Indian food delivery app, Zomato:

3. Build intelligent workflow designs

Arjun Narayan, founder and CEO of Sales Duo very aptly says that “the key to streamlined order management isn't just software—it's intelligent workflow design.”

He expands on four key components:

- Implement automated order routing based on fulfillment rules. Set up rules to direct orders based on factors like shipping destination, product type, or inventory levels. For example, route fragile items to specialized packing stations, or send urgent orders to the nearest fulfillment center.

- Maintain real-time inventory sync across all channels. Keep your inventory data in sync across all your sales channels, including in-store customer places and online marketplaces. This allows for greater omnichannel order accuracy and fewer customer disappointments.

- Establish clear SLAs for each order stage. Establish clear service level agreements (SLAs) for each stage of the order process. Define expectations for processing times (e.g., 24 hours for order verification), shipping speeds (e.g., next-day delivery for express orders), and return handling (e.g., 48 hours for processing refunds). SLAs help you track performance and ensure everyone's on the same page.

- Most critically, choose an OMS that integrates seamlessly with your existing tech stack. Your order system needs to play nice with your other tools. Your ecommerce platform, CRM, marketing tools, shipping software—they should all be able to “talk” to each other. This streamlines data flow and reduces errors.

4. Combine automation with project management frameworks

Tom Golubovich, head of marketing at Ninja Transfers, told me how he uses the Kanban system for order management—a brilliant way to visualize your inventory workflow and keep everyone on the same page! (Quite literally).

Here’s how:

“Using simple visual boards, we divided our process into stages like “New Order,” “In Production,” “Quality Check,” and “Ready to Ship.”

The team moves tasks across these columns, so we always know where each order stands. This simple system reduced miscommunication drastically. Combined with ShipStation, our processing hours for an average week dropped from 10 to 6, freeing up four hours for the team to focus on new designs and customer support.”

5. Prioritize small-batch orders

Instead of dealing with a massive wave of orders all at once, break it down into smaller, more manageable ripples.

This allows your team to focus, minimize inefficiencies, and keep things moving smoothly for on-time delivery.

So says Roman Zrazhevskiy, founder and CEO of MIRA Safety:

One overlooked strategy we swear by is prioritizing small-batch orders.

We discovered that processing and shipping smaller, more frequent batches reduced bottlenecks during peak periods.

This method improved fulfillment accuracy to 99.6% and significantly reduced re-shipments.

Here are a few ways to effectively implement a small-batch order strategy:

- Set batch sizes. Determine the optimal batch size for your operation, considering factors like order volume, team size, and processing capacity.

- Prioritize batches. Establish a clear prioritization system for your batches. This could be based on factors like shipping deadlines, order value, or customer location.

- Dedicate resources. Consider assigning dedicated resources to each batch to ensure focused attention and accountability.

6. Forecast demand with predictive analytics

Looking at the past helps you predict future product needs and improve inventory visibility across the board:

- Prevent stockouts. Avoid those frustrating “out of stock” situations that disappoint customers and hurt your bottom line.

- Optimize inventory levels. Don't tie up valuable capital in excess inventory. Forecast demand to stock just the right amount of product.

- Reduce waste. Minimize waste by accurately predicting which products will sell and when.

- Improve operational efficiency. Streamline your supply chain and make sure you have the right products in the right place at the right time.

While predictive analytics assisted in forecasting demand, which resulted in a 22% reduction in stockouts, automating repetitive operations with Zapier resulted in a monthly savings of 20 hours.

7. Optimize order routing and shipping processes

Getting your products from “click” to “doorstep” quickly—and affordably—is the name of the game in ecommerce. That's where optimizing order routing and shipping processes comes in.

The goal is to pair each order with the most logical shipping origin. This could be based on factors like:

- Proximity to the customer. Shipping from the nearest fulfillment center reduces transit times and shipping costs. Happy customers, happy wallet!

- Inventory levels. Route orders to the location where the product is readily available to avoid delays and backorders.

- Shipping costs. Factor in shipping costs from different locations to find the most economical option. Sometimes, a slightly longer distance might cause lower overall shipping costs.

- Special handling. If an order requires special handling (e.g., fragile items), route it to a fulfillment center equipped to handle those needs.

Automate your shipping processes with software that can compare rates, print labels, and track shipments:

8. Empower customers with self-service

We’re pretty savvy shoppers now—give us the information we want and need, and we’ll work out the rest.

(And whenever we can avoid speaking to someone, that’s always welcome.)

A significant majority (77%) of customers (yours truly included), react more favorably to brands that provide self-service support.

This is one of those situations where being more hands-off can actually strengthen your customer relationships, so:

- Build a killer knowledge base. A comprehensive and easily searchable knowledge base is the cornerstone of effective self-service. Think FAQs, tutorials, how-to videos—anything that empowers customers to find answers quickly.

- Optimize for mobile. This includes everything from responsive design to fast-loading visuals to mobile-first content.

- Get AI chatbots running. They can answer common questions, guide customers through troubleshooting steps, and even escalate complex issues to human agents when needed.

Future Trends in Order Management

Of the 30+ experts I spoke with, the majority of them (27) had two things on the brain—AI and sustainability.

AI-powered efficiency

Think automation on steroids (or really expensive protein powder) with a dash of personalization.

Here’s what David Speedy, general manager at Workspace Direct has to say:

A big trend emerging in order management for 2025 is the use of AI-powered predictive analytics.

This technology looks at customer behavior, order history, and market trends to predict demand with more accuracy.

With this insight, businesses can fine-tune their inventory levels, avoiding both stockouts and overstocking.

AI helps companies anticipate order volumes, which allows them to streamline supply chains, shorten lead times, and boost customer satisfaction.

This proactive strategy also makes it easier to allocate resources efficiently and fulfill orders more quickly.

We’ll also see even more personalized customer experiences, with tailored recommendations and quicker responses.

Sustainability takes center stage

Eco-conscious is the new black. Customers care about the planet, and so should your order management.

- Eco-friendly everything. Think recycled packaging, sustainable shipping, and transparent sourcing. (That’s how we built trust with our customers!)

- Green is the new gold. Attract environmentally conscious customers (there are a lot of us…) and reduce your carbon footprint.

Sustainability is only going to get more and more attention.

Customers really want to know how their products are sourced and shipped, so brands will have to adopt more eco-conscious methods.

Whether that’s in packaging, shipping, or both. And that’s a wonderful trend to be welcoming.

From Click to Doorstep

Whether you're shipping from your living room like my mother and I did, or running a full-scale warehouse operation, here's the deal:

- Inventory management tools eliminate those stomach-dropping moments of overselling your bestsellers.

- Real-time tracking turns the dreaded “Where's my package?” into excited “It's almost here!” messages.

- AI predicts what your customers want before they know they want it, keeping your warehouse stocked and your business flowing.

And as Mike from FoamOrder points out, customers care about the whole order journey now.

They want their packages delivered with purpose, packed with conscience, and shipped with the planet in mind. Meanwhile, AI keeps making everything faster, smoother, and smarter.

So, put down that spreadsheet (really, it's time). Build systems that grow as you grow.

The world of ecommerce moves fast—and so do you. Subscribe to our newsletter with the latest insights for ecommerce managers from leading experts in the industry.