The Delivery Dilemma: The intricacies of order delivery can make or break customer satisfaction, highlighting the importance of streamlined processes involving numerous logistical steps to ensure timely and accurate deliveries.

Logistics—Friend or Foe?: Logistics play a crucial role in order fulfillment, where efficient management is key to preventing mishaps and ensuring that orders arrive as expected, avoiding potential nightmares.

The Order Odyssey: Every order begins a journey filled with potential challenges and triumphs, emphasizing the need for robust systems to navigate complexities from warehouse to doorstep.

Streamlining Success: Optimizing logistics processes helps in turning potential order issues into seamless experiences, ensuring customer satisfaction and loyalty through reliable delivery performances.

The Path to Customer Happiness: Ensuring that orders reach customers smoothly is vital for businesses, requiring meticulous planning and execution of logistical operations to fulfil customer expectations consistently.

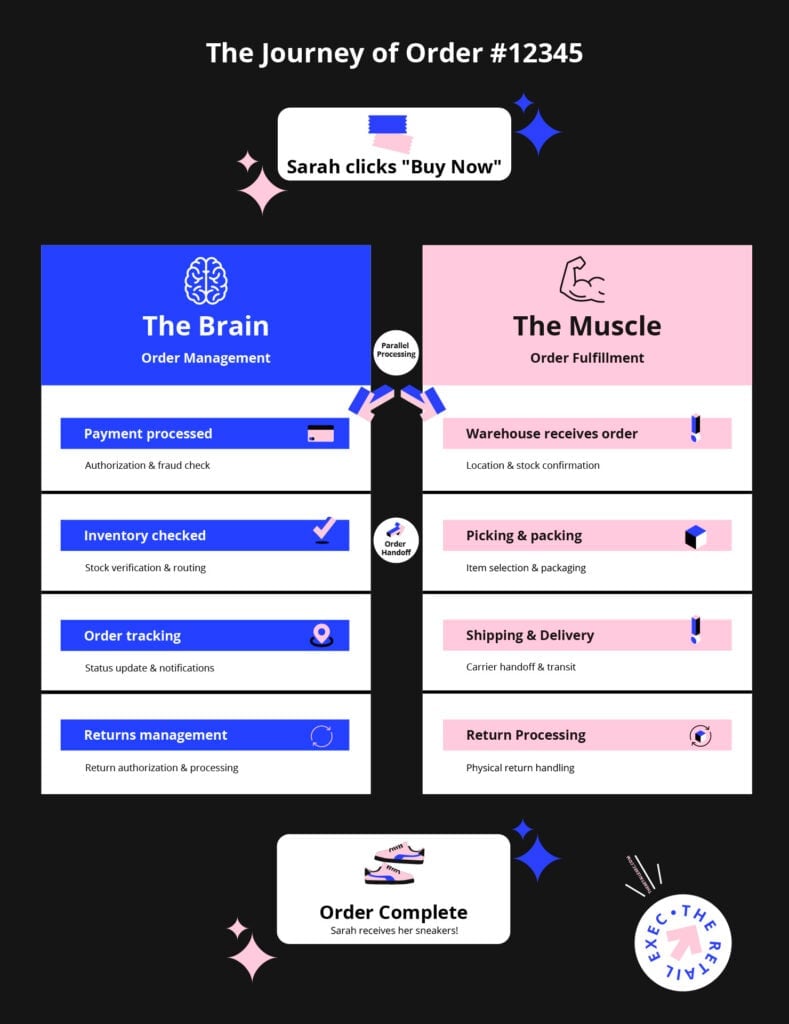

Two critical processes determine whether a customer's order arrives on their doorstep or becomes a logistics nightmare.

Order management coordinates the entire order lifecycle, including payment processing, inventory tracking, and customer communications, while order fulfillment handles the physical tasks of picking, packing, and shipping products to customers.

When Sarah clicked “Buy Now” on her limited-edition sneakers at 2 AM, she had no idea her order would trigger a chain reaction across three warehouses, two shipping carriers, and one very determined operations team.

Order #12345 was about to begin its journey through the complex world of retail operations.

But before we follow Sarah's sneakers from warehouse shelf to doorstep, let's address the fundamental confusion that keeps many ecommerce operators awake at night: why the distinction between these processes even matters.

While order management orchestrates the entire lifecycle of an order from purchase to delivery, order fulfillment handles the physical journey of getting products into customers' hands.

This distinction isn't just academic—it's the difference between a seamless customer experience and a logistical nightmare.

When these processes become tangled, it's not just about misplaced packages or delayed shipments. It's about disappointed customers, overwhelmed staff, and the ripple effects that can shake a business to its core.

The stakes are immediate and far-reaching.

Just ask James, the operations manager who spent his Sunday morning trying to track down Sarah's sneakers across three warehouses because the inventory system showed stock that didn't actually exist.

Through Sarah's sneakers, we'll see exactly how these processes work together—and sometimes collide—in the real world of modern retail.

What is Order Management?

As Brinda brilliantly put it in her big guide to order management, biting into a sour orange leaves the same taste as telling your customer “Sorry, we can't find your order” or “Oops, looks like we oversold that item!”

Order management is the entire customer order lifecycle—from the moment someone smashes that “buy” button until their package lands at their doorstep.

For ecommerce, think of routing orders to warehouses, processing orders through manual processes, printing shipping labels, handling returns, and keeping subscription customers happy.

Let's walk through what this actually means by stalking Order #12345—Sarah's shiny new sneakers:

- Order processing. Sarah clicks “buy” and boom—the system springs into action, capturing her details, checking her payment isn't dodgy, and firing off that sweet order confirmation email. Behind the scenes, it's figuring out which warehouse can get those kicks to her fastest.

- Inventory management. This is all about answering that anxiety-inducing question: “Do we actually have the thing we just sold?!” The system checks stock levels, updates counts (so we don't accidentally sell Sarah's sneakers twice), and waves red flags when we're running low.

- Payment processing. Making sure Sarah's payment goes through without a hitch. Because there's nothing worse than having to email a customer saying “Hey… about that order…”

- Order tracking and updates. Keeping Sarah in the loop as her sneakers make their journey. Turning that nail-biting “Where's my stuff?!” into excited “It's almost here!” moments.

- Returns and exchanges. If those sneakers don't fit quite right, making sure Sarah isn't stuck doing the return-label shuffle or playing email tag with customer service.

Why does nailing this matter? Because poor order management is like those sour oranges—leaving a bad taste that keeps customers from coming back.

Good order management means:

- Happy customers (who leave those sweet, sweet 5-star reviews)

- Efficient operations (no more 3 AM panic about lost orders)

- Smart inventory control (preventing those “sold out AGAIN?!” moments)

- Major cost savings (fewer mistakes = more money in your pocket)

What is Order Fulfillment?

Think of order fulfillment as the muscle behind your store's brain.

While effective order management tracks Sarah's sneakers (Order #12345!) in the system based on the customer's location, fulfillment is getting those right products from the warehouse shelf to happy customer hands.

Kate from Irresistible Me breaks it down perfectly:

Order fulfillment is where the rubber meets the road—it's the physical process of picking products off shelves, packing them properly, and shipping them to eager customers.

All the fancy systems in the world won't matter if you can't nail this part.

Here's what goes into making sure Sarah gets her sneakers:

- Warehouse management. Making sure those sneakers are exactly where the system says they are (no wild goose chases!), keeping the space organized, and maintaining proper stock levels.

- Picking and packing. Grabbing the right size, color, and style (no accidentally sending Sarah size 9 when she ordered size 7!), and packaging them safely.

- Shipping and delivery. Getting those kicks from point A to point B without playing hot potato with the package. This means choosing the right carrier, printing accurate labels, and tracking every step.

- Returns processing. If those sneakers don't fit quite right, making the return process smooth as butter. Sarah gets clear instructions, an easy-to-print label, and quick processing. In fact 72% of customers show greater loyalty to brands that offer free returns!

Why does all this matter? Because in ecommerce, you're only as good as your last delivery.

In fact, 84% of shoppers say they won't return to a retailer after just one poor delivery experience. One fumbled fulfillment can turn a potential brand advocate into a one-time buyer.

And in a world where customers expect Amazon-level efficiency (thanks, Jeff), nailing your fulfillment process isn't just nice—it's necessary.

Order Management vs Order Fulfillment: Key Differences

The tension between system data and reality, highlights the critical distinction between order management and fulfillment.

When the order fulfillment process isn't in sync with the order management process, it creates both personal stress... (“Will I find these sneakers before Sarah wakes up and checks her order status?”) and operational chaos (“How many other orders might have this same problem?”).

Let's break down exactly where these two processes diverge, and why getting them to work together matters more than ever:

Key responsibilities

| Aspect | Order management | Order fulfillment |

|---|---|---|

| Scope | Runs the whole omnichannel show—from "Order Placed" to "Package Delivered" across multiple marketplaces and websites. | The behind-the-scenes hustle of getting products out the door. |

| Order capture | Catches incoming orders, verifies details, and sends them where they need to go. | Gets the order and starts the real work—picking, packing, and prepping. |

| Inventory management | Keeps an eye on stock levels, triggers reorders, and hopes the numbers add up. | Physically counts, stores, and organizes products (and finds out why there are always two missing). |

| Payment processing | Handles payments, refunds, and those dreaded declined transactions. | No money talk here—just moving goods. |

| Order tracking | Sends those “Your order is on the way!” updates (because customers check 10 times). | Prints labels, hands off packages, and makes sure they get moving. |

| Returns management | Deals with the "this isn’t what I expected" returns and refund drama. | Inspects returned items and decides their fate—restock, refurbish, or reject. |

Tools & technology

| Aspect | Order management tech | Fulfillment tech |

|---|---|---|

| Software used | The brains of the operation—OMS platforms like Linnworks for multichannel magic, Cin7 Core for manufacturers, and NetSuite for enterprises. | The muscle behind fulfillment—ShipBob for global reach, ShipStation for seamless shipping, and Softengine for mobile-first operations. |

| Automation features | Smart order routing that works while you sleep, inventory alerts that actually warn you before stockouts, and payment processing that runs itself. | Barcode scanning that keeps things accurate, automated pick lists that make sense, and even robotic helpers (if you're living in the future). |

| Data management | Real-time inventory sync across all sales channels (so you don’t sell what you don’t have), order history tracking, and predictive analytics that actually help you plan. | Pick lists that update instantly, location tracking that doesn’t leave you guessing, and shipping data that helps cut costs and speed up deliveries. |

| Operational workflow | Smarter order routing rules, VIP order flagging for high-priority shipments, and returns automation that doesn’t turn into a nightmare. | Digital picking routes that don’t send staff on scavenger hunts, packing station workflows that actually flow, and shipping optimization that keeps costs down. |

Challenges faced

| Challenge | Order management headaches | Order fulfillment facepalms |

|---|---|---|

| Multichannel complexity | Keeping orders from Shopify, Amazon, and Instagram in sync while maintaining accurate stock levels across all channels. | Making sure the right orders go out when your warehouse is juggling different platforms—especially those last-minute TikTok orders. |

| Inventory visibility | The system says you have 50 in stock, but does reality agree? Keeping inventory turnover and accurate SKUs across channels without losing your mind. | Tracking down products the system swears are in Aisle 3 but seem to have vanished into thin air. |

| Customer expectations | Managing the “Amazon Effect”—where instant order processing isn’t a perk, it’s expected. | Racing against the clock to fulfill orders because “2-day shipping” now feels like “2-hour shipping.” |

| Returns & refunds | Processing refunds fast enough to keep customers happy while keeping inventory records accurate. | Inspecting returns that look like they’ve been through a battle and deciding if they’re resellable or headed for the trash. |

The Relationship Between Order Management and Order Fulfillment

Think of order management and order fulfillment as the dynamic duo of retail operations—like Batman and Robin, but with spreadsheets and shipping labels.

Order management is the brain—coordinating the entire journey of Order #12345 (Sarah's sneakers) by capturing her purchase, validating payment, and routing the order through the system.

Order fulfillment is the muscle—executing the physical tasks of grabbing those specific sneakers from the warehouse shelf, carefully packing them, and ensuring they hit the right shipping route.

When these processes sync up perfectly, it's retail poetry in motion while doubling up your conversions. In fact, 70% of consumers say that a positive delivery experience makes them more likely to shop with a retailer again.

But when they don't?

That's when operations managers like James start pulling their hair out, tracking phantom inventory and dealing with customer complaints. Just like James, more than 43% of retailers cite order fulfillment as their biggest challenge.

Good luck selling those sneakers if your system can't even tell you where they're hiding!

By leveraging integrated software solutions that can instantaneously update inventory levels, route orders to the optimal warehouse, and track every movement in real-time, businesses can create a near-seamless experience that makes customers feel like their order is the only one that matters.

So, what happens when Batman and Robin join forces?

Sarah gets her dream sneakers with minimal friction, the business maintains accurate inventory, and the entire operation runs with the precision of a well-oiled machine.

How to Optimize Order Management and Fulfillment for Retail Success

When Sarah clicked “Buy Now” for her limited-edition sneakers at 2 AM—she had no idea she was about to become the ultimate stress test for an entire ecommerce operations team.

What should have been a simple 2 AM purchase turned into a logistical thriller that would make even the most seasoned operations manager break into a cold sweat.

The inventory system said the sneakers were in stock.

The warehouse? Totally different story.

Cue the dramatic music (okay, maybe no music—James from operations is definitely not in a singing mood).

It wasn't just about one missed order. Every error compounded the risk: a negative review here, a refund there, customers jumping to competitors with just a few clicks.

The ecommerce landscape was unforgiving, and their current operational model was a house of cards ready to collapse.

For companies drowning in operational chaos, this is the moment of truth. Here's how smart brands are turning potential logistical nightmares into seamless customer experiences:

Step 1: Implement integrated software solutions

For Order #12345 to reach safely, we need three powerful systems to work together.

- The moment an order entry happens and Sarah clicks “Buy Now,” the order management system (OMS) springs into action. It captures her payment and order details faster than you can say “checkout” (not sure why you’re saying that, but whatever).

- Meanwhile, the warehouse management system (WMS) is already plotting the most efficient route to grab those size 7 sneakers from the shelf.

- The enterprise resource planning system (ERP) watches over the entire operation, tracking every financial nuance and operational detail, so that nothing is unaccounted.

At the heart of this is inventory forecasting, that does more than just count shoes.

These advanced algorithms dive deep into a data ocean. They are able to analyze past sales patterns and seasonal trends to social media buzz and upcoming events that might spike demand for limited-edition sneakers.

It calculates with laser precision, understanding that those size 7 sneakers aren't just an item, but part of a complex ecosystem of consumer behavior.

By processing millions of data points, the forecasting technology can predict exactly how many pairs will sell, when they'll sell, and even anticipate potential supply chain disruptions.

The result? Sarah gets her sneakers exactly when she wants them. Plus, the company turns a complex operational challenge into a moment of profit and satisfaction!

Want the best software for order management? We did the hard work for you :)

Oh, and we didn’t forget the best order fulfillment service options. Here you goooo!

If your order process feels like an ancient ritual, it’s time for an upgrade. These order entry tools make life a whole lot easier.

Step 2: Enhance inventory visibility and accuracy

Remember James hunting for Sarah's sneakers across three warehouses?

That's what happens when your inventory visibility is about as clear as mud on a rainy day. Let's fix that before another operations manager loses their weekend to the “Where's Waldo?” of warehouse management.

Smart brands are revolutionizing their inventory game by:

- Implementing cycle counting programs that make annual stock takes feel like ancient history

- Using RFID technology to track inventory movement faster than you can say “Where did those sneakers go?”

- Setting up automated alerts that ping you before stock hits critical levels (no more emergency supplier calls at midnight!)

- Creating a single source of truth across all sales channels (because selling the same pair of shoes twice is so last season)

Doing all of this is absolutely important—because in the world of ecommerce, being “pretty sure” about your stock levels is about as useful as a chocolate teapot.

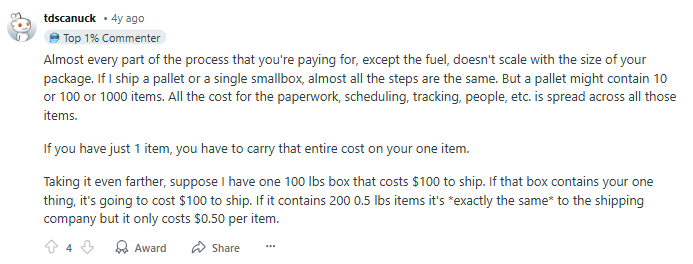

But if you’ve ever thought about how a store's inventory software stays in sync with physical goods on the shelf—then here’s a Reddit user speaking from his experience!

TL;DR: Most retail outlets use pallets and barcode inventory systems along with a manual check yearly. This is to make sure the system is not out of sync due to theft, damaged items or checkout operation errors.

Step 3: Automate order routing for efficiency

Smart order routing is an intelligent system that processes multiple variables in real-time.

The moment an order hits, routing algorithms spring into action like caffeinated mathematicians, calculating shipping costs, delivery times, inventory levels, and warehouse capacity.

These split-second decisions have transformed shipping costs and delivery times.

But the real game-changer comes through strategic 3PL partnerships. Instead of being stuck with one lonely warehouse in Kansas trying to serve customers everywhere, brands can leverage networks of warehouses across different regions.

Modern 3PLs bring the whole package—they scale up during busy seasons, save you from building expensive warehouses, and bring expertise that would take years to develop in-house.

In fact, outsourcing your logistics to 3PL increases your retention rate by 36%.

The key is choosing partners with compatible technology stacks and robust API integration capabilities to ensure seamless inventory synchronization and real-time order routing.

Implementation requires careful attention to several critical factors:

- API integration between systems

- Real-time inventory synchronizati

- Custom business rules for special handling

- Comprehensive performance monitoring.

Successful routing automation depends on establishing clear service level agreements and maintaining consistent communication channels with 3PL partners.

Also, if you’re looking for game-changing automation solutions that won't require selling your firstborn to implement, we have that list ready for you:

Step 4: Streamline warehouse operations

When Sarah's sneakers need to go from shelf to shipping dock, every second counts.

Smart warehouses use barcode scanning and RFID technology to track inventory movement to prevent any “I swear it was right here yesterday” moments.

Key optimization strategies include:

- Strategic slotting: Putting fast-moving items in prime picking locations.

- Wave picking: Grouping similar orders to reduce warehouse walking time.

- Zone picking: Assigning pickers to specific areas (like sorting your closet, but profitable).

- Quality control checkpoints: Because nobody wants to explain why Sarah got size 9 instead of size 7.

The real breakthrough comes from integrating these systems with your inventory management software. When a picker scans Sarah's sneakers during the process of receiving, the system automatically:

- Updates inventory counts in real-time

- Validates the correct item was picked

- Triggers replenishment if stock runs low

- Records picking speed and accuracy metrics

If you ever questioned how delivery companies like UPS and FedEx deliver your packages so quickly when the item is on the other side of the country—then here is your handy Reddit commenter answer:

TL;DR: The key to fast delivery is ride-sharing and central hubs in cities. By making such strategic choices, companies like FedEx and UPS have logistical operations that could put 99% of the countries to shame :)

If your warehouse is starting to feel like a storage unit, it’s time to look into cross-docking.

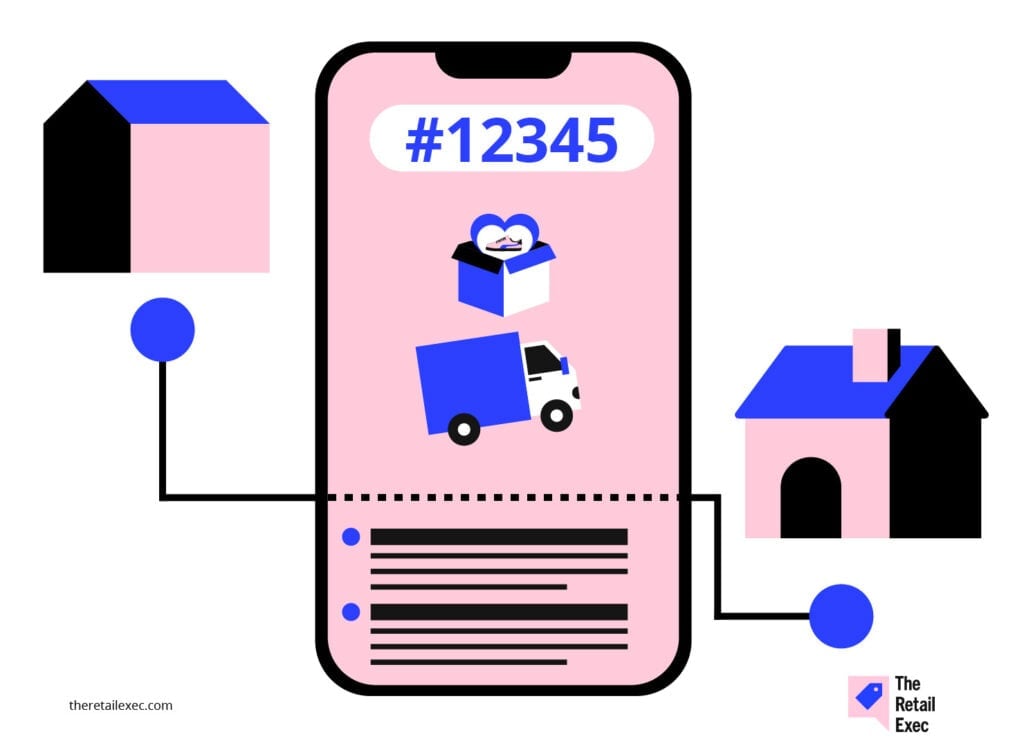

Step 5: Provide real-time order tracking

Remember Sarah anxiously checking her phone for updates on those limited-edition sneakers?

Automated shipping notifications have become the heartbeat of customer satisfaction. From order confirmation to delivery, each status update reduces support tickets and builds trust.

Here's what smart brands are doing:

- Sending SMS and email notifications at key journey points

- Providing visual tracking maps (because watching your package travel is oddly satisfying)

- Offering estimated delivery windows based on real-time carrier data

- Alerting customers about potential delays before they become issues

But while you’re sending all this tracking information, it is necessary to make sure that all the tracking information is easily accessible.

Your tracking portal should:

- Be mobile-friendly (because who checks shipping updates on desktop?)

- Show order status in plain English or which ever language your customer speaks in (not cryptic shipping codes)

- Include package photos when available

- Provide instant support options if something looks wrong

When delays happen (because sometimes they do), proactive communication turns potential frustration into understanding. Because let's face it—customers can handle delays, but they can't handle being left in the dark.

How SovTech built a smarter retail tracking system 📲

SovTech transformed a struggling retail operations system by building a mobile app that solved critical tracking and communication challenges.

The company implemented a geolocation feature integrated with Google, enabling administrators to proactively track driver locations and order statuses in real-time.

By developing an innovative multi-factor login system and centralizing order management, they shifted from reactive damage control to proactive monitoring. The solution included a mobile app for drivers and a progressive web app for administrators, providing offline access and improving performance while reducing data usage.

Ultimately, SovTech's dual-track agile approach allowed for faster delivery, regular feature additions, and a seamless technology integration that enhanced the entire operational ecosystem.

Step 6: Simplify returns and refunds

Modern returns management has evolved from “email us and wait forever” to “click, print, return, refund.”

Data shows that 72% of shoppers say that when a retailer offers free returns, it increases their loyalty to that retailer. No pressure, right?

Here's what efficient returns best practices look like:

- Automated return authorization (no more playing email tag)

- Self-service return portal (because customers want control)

- QR code-based return labels (easier than trying to keep track of paper)

- Instant refund triggers once items are scanned back into the warehouse

- Smart disposition routing (automatically sorting returns into resell, repair, or recycle)

The secret sauce is integration. Your returns system should automatically:

- Update inventory counts when returns are initiated

- Flag problematic return patterns

- Process refunds without manual approval for standard cases

- Track return reasons for product improvement insights

A great return after all isn't just good customer service—it's good business.

Step 7: Cut shipping costs strategically

Shipping costs can eat into profits faster than a warehouse full of hungry pickers.

But for Order #12345’s company—they need to deliver speed without bleeding money on every package. In fact, 30% of online shoppers abandon their carts due to slow shipping speeds.

So modern shipping process optimization is about leveraging speed, data, and technology. Here’s how:

- Rate shopping across carriers for each package

- Zone skipping for bulk shipments to similar regions

- Strategic carrier mix based on package size and destination

- Local pickup options for urban customers

- Packaging optimization (because shipping air is expensive)

So the real secret sauce is in bulk booking or sending items, a Reddit user explains this really well:

TL;DR: Bulk booking can be cheaper than single package delivery, since the cost for the paperwork, scheduling, weight and tracking is spread across items.

The real powerhouse here is multi-carrier shipping software.

These systems automatically compare real-time carrier rates, identify the most cost-effective service levels, and manage bulk shipping discounts.

They track carrier performance metrics and handle paperwork for international shipments, turning what used to be hours of manual work into automated efficiency.

Ready to stop overpaying for shipping? We've analyzed the top shipping software solutions that won't require a PhD in logistics to use.

Step 8: Track performance and optimize continuously

What gets measured gets improved. Just ask James, who used to track warehouse performance with a combination of spreadsheets and crossed fingers.

Modern analytics have transformed guesswork into data-driven decisions that keep operations running smoothly

Performance tracking starts with the four horsemen of fulfillment metrics:

- Order accuracy rate because sending the wrong sneakers is expensive

- Fulfillment speed because “fast” is the new “normal”

- Return rates because sometimes size 7 feels more like a 6

Finally, customer satisfaction scores because happy customers keep clicking “buy”

Data data data, I can’t make bricks without clay.

– Sir Arthur Conan Doyle

Modern analytics platforms turn raw data into actionable insights by:

- Identifying bottlenecks in real-time before they become problems

- Predicting busy periods so you can staff appropriately

- Spotting trending products to optimize inventory placement

- Tracking carrier performance to negotiate better rates

- Monitoring customer feedback patterns to improve processes

The key is to convert data into actions that impact the bottom line. Because in the end, the best fulfillment metrics are the ones that keep customers coming back for more.

Did Sarah Get Her Limited Edition Sneakers?

In today's “I want it now” ecommerce world, order management and fulfillment must work together perfectly.

Order management orchestrates the entire process—from purchase flows and inventory checks to customer communications. Meanwhile, fulfillment handles the physical journey, turning digital orders into packages that land on doorsteps.

The magic happens when these systems work together seamlessly.

When Sarah clicks “buy,” she doesn't care about the complex process happening behind the scenes. She just wants her sneakers to arrive on time, in the right size, and in perfect condition.

Making that happen consistently requires more than just hope—it takes integrated technology, smart automation, and constant optimization.

For brands still running operations on spreadsheets and sticky notes (we see you), now's the time to level up. The ecommerce landscape is moving faster than ever, and staying competitive means embracing tools that scale with your growth.

And what about Order #12345?

Those limited-edition sneakers that started our journey? They were picked, packed, and delivered to Sarah's doorstep in under 48 hours.

No warehouse hunting, no missing inventory, no emergencies. Just smooth, efficient operations turning a 2 AM purchase into another happy customer.

James even got to enjoy his Sunday morning coffee in peace.

Because that's what great order management and fulfillment integration looks like—not just systems and processes, but getting products to customers exactly when and how they expect them.

The world of ecommerce moves fast—and so do you. Subscribe to our newsletter with the latest insights for ecommerce managers from leading experts in ecomm.